News Clips

- Published: September 01, 2007

Covering the Full Spectrum of Industry News, Events & Activities

NEWS BRIEFS

- The Foodservice & Packaging Inst., Falls Church, VA, offers a new leaflet on “Foodservice Packaging and the Environment,” addressing issues related to solid waste, litter, recycling, waste-to-energy, and sustainable materials and packaging. For a PDF version of the leaflet, visit fpi.org.

- SATO, supplier of barcode printing, labeling, and EPC/RFID solutions headquartered in Charlotte, NC, has established three new regional headquarters: SATO Intl. Asia-Pacific, Singapore; SATO Intl. Europe, Belgium; and SATO Intl. America, Charlotte, NC.

- FKI Logistex, St. Louis, MO, is bringing together three existing Canadian divisions to form FKI Logistex Canada Ltd. Company management veteran Steve McElweenie will serve as VP and general manager, working in the Toronto area.

- Winkler+Dünnebier, Neuwied, Germany, manufacturer of envelope and handkerchief machines, celebrated the opening of its new subsidiary enterprise in Malaysia with an open house and a demonstration of the company’s newly developed basic machine, the W&D 320.

- Atlas Die, Elkhart, IN, has acquired all the business operations and assets of Gardall Mfg. Corp., Wood Dale, IL, a manufacturer of rotary dies, print cylinders, and anvils.

- The Assn. of Industrial Metallizers, Coaters and Laminators, Fort Mill, SC, and the Society of Vacuum Coaters, Albuquerque, NM, have established a scholarship in the name of Dr. Bernard Henry of Oxford Univ., who passed away recently.

- Dow Reichhold Specialty Latex, Research Triangle Pk., NC, has decided on a name for its patent-pending technology to produce emulsion polymers. The technology platform will be designated PolySaf Antimicrobial Polymers.

-

A Long, Green History

BENNINGTON, NH | Monadnock Paper Mills says it not only has the oldest continuously operating mill in the US (starting in the 1800s), but it also has a commitment to environmental responsibility that goes back to the beginning.

Monadnock reports it was the first paper mill in the country to receive Forest Stewardship Council (FSC) certification for its Astrolite PC 100 premium 100% post-consumer fiber paper that is process chlorine free and of archival quality. The company announces that all of its Graphic Arts and Packaging papers now are made with 100% renewable electrical energy and manufactured carbon neutral.

Located next to the Contoocook River, Monadnock uses the flow of the river to generate “green” electricity. In addition, the company reports it has accomplished the following:

- doubled its purchase of post-consumer reclaimed material in the past two years;

- increased recycling rates by 80% in two years;

- generated 49% of its electricity from water power from its own on-site, low-impact hydroelectric turbines;

- launched the all-new FSC Certified Envi, a high-caliper paperboard for folding box applications with high (65%–80%) post-consumer waste content.

Expanding into Packaging

Fong Brothers, a commercial printer in Brisbane, CA, has added packaging and folding cartons printed on heavier board to its offerings. Aiding that effort is a six-color, 40-in. Mitsubishi Diamond 3000LX sheet-fed press that handles stock from 0.002-0.040 in., including paper, board, and synthetic substrates. Company president Tony Fong says, “We print a lot of product boxes for the technology industry. This press will allow us to print regular commercial projects but also will provide greater flexibility in the types and sturdiness of cartons the company can produce.”

As the owner of other Mitsubishi presses, Fong says, “We know from experience that Mitsubishi can compete against any other press as far as printing quality and performance.… We have been most impressed with…the way the company stands behind its equipment.”

Mitsubishi Lithographic Presses | mlpusa.com | PFFC-ASAP 325

Coatings Pass the Test

CINCINNATI, OH | Michelman reports it has passed the repulpability portion of the updated Fibre Box Assn. (FBA) Protocol at the Western Michigan Univ. School of Paper Engineering for a series of its barrier, functional, and decorative coatings. The protocol, developed by a joint committee of the FBA and the American Forest and Paper Assn., tested VaporCoat 330C and Michem Coat 40EAF wax replacement coatings for use on fruit, vegetable, and protein/meat boxes; Nomar 70AF, an abrasion-resistant coating; Coating X300AF, a water-resistant coating; and MaxWhite 17, a decorative white coating.

New Site Will Help Cut Waste

MERRILLEVILLE, IN | MonoSol finalizes the purchase of a 15-acre industrial greenfield site in La Porte, IN, to complement manufacturing operations in Portage, IN, and Hartlebury, England. The site will feature an $11 million facility with high-tech film production lines and pilot testing laboratories. P. Scott Bening, MonoSol’s president and CEO, reports, “Products manufactured in the new facility will include those made from renewable biopolymer and repulpable materials, which help to reduce overall packaging waste. Specialty edible films for unit-dose and portion control for food manufacturers and consumers also will be at the new facility.”

New Press, Same Supplier

Global Packaging, Oaks, PA, bought its first Windmoeller & Hoelscher press in 2004, a ten-color Novoflex CM. So when the converter needed to add another press, it turned again to W&H. The new model is a 52-in., eight-color Primaflex CM. Company president Michael Frost says the new press will add significantly more printing capacity for the company, which specializes in branded and private label packaging for markets that include personal hygiene and diaper products, cosmetic and paper products, and food packaging.

“We have always purchased the best printing equipment available in the marketplace, and the Primaflex is a continuation of this approach,” says Frost.

The new Primaflex CM has production speeds to 1,300 fpm and print repeats ranging from 14.5–31.5 in. It includes W&H’s Turboclean 600A inking and wash-up system that automatically cleans the printing decks, anilox rolls, and doctor blade chamber and is suited for both solvent- and water-based inks.

“The press is designed to print top quality product at high line speeds, while allowing for fast job changeovers,” says Frost. “[It] will help [us] fulfill our commitment to our customers to consistently deliver high quality printed packaging with excellent lead times.”

Windmoeller & Hoelscher Corp. | whcorp.com | PFFC-ASAP 326

EDI Adds Slot Die Company

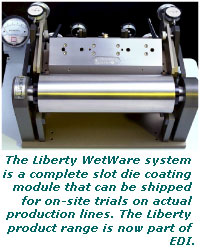

CHIPPEWA FALLS, WI | Extrusion Dies Industries (EDI) has purchased Liberty Coating Equipment, a manufacturer of slot die coating systems. EDI will retain the Liberty product range and trade name but will move all manufacturing systems from Liberty’s plant in Sussex, WI, to EDI headquarters in Chippewa Falls. Joining EDI as product manager for Liberty systems is Tom Johns, formerly design and application engineer with Liberty. EDI project and manufacturing engineer Mark D. Miller will serve as manager in charge of all Liberty accounts. Although EDI is also a supplier of slot die systems, there is little overlap between their customer bases, says Christopher W. Curtin, EDI’s executive VP of sales and marketing. “The acquisition…enables EDI to expand its reach in a number of slot die markets, particularly those requiring very thin optically clear coatings.”

PIMA Hands Out Awards

NORCROSS, GA | PIMA, the Paper Industry Management Assn., presented its top awards during the recent 2007 TAPPI Papermakers & PIMA International Leadership Conference.

Keith Van Scotter, president of Lincoln Paper and Tissue, was named PIMA’s 2007 Executive of the Year; John “Jay” Martin, paper mill superintendent at Graphic Packaging Intl.’s Macon, GA, mill, was named the Brookshire Moore Superintendent of the Year; John Donahue, managing director of SAPPI Fine Paper North America’s Somerset operation, is the Mill Manager of the Year; and Russ Bishop, director of IT manufacturing for Weyerhaeuser Co., is Technologist of the Year.

The conference was a collaboration between TAPPI and PIMA.

For more information visit pimaandtappi.org.

Gearless Press on Display

TAVAZZANO, ITALY | Flexotecnica recently opened its global headquarters near Milan for a demonstration of the 52-in., eight-color Chronos sleeved gearless press. The press on display offered a maximum printing speed to 1,150 fpm; a drying tunnel with 16 nozzles; a repeat range from 14.6-31.5 in.; flying splice unwind and rewind for maximum roll diameters of 39.3 in; an AVT PrintVision Prelude video camera for web inspection and auto register control; a Speedy Clean automatic wash-up system; and a Fife edge guiding system.

FPA Offers Scorecard “Class”

By Deborah Donberg, Associate Managing Editor

ROSEMONT, IL | Converters and materials suppliers gathered June 19 at the Hyatt Regency O’Hare in Rosemont when the Flexible Packaging Assn. (FPA) conducted a workshop on the Wal-Mart Scorecard. The meeting (with PFFC in attendance) was facilitated by consultants Packaging & Technology Integrity Solutions (PTIS).

The scorecard is Wal-Mart’s way of judging the packaging of its suppliers in regard to environmental factors such as recyclability, weight, and transportation.

FPA president Marla Donahue acknowledged the skepticism of many consumer packaged goods companies (CPGs) regarding the scorecard, at least as far as the Feb. 1, 2008, deadline is concerned. Of 66,000 suppliers to Wal-Mart, less than 2,000 had logged on to the scorecard by the meeting date.

The sustainable packaging initiative in general is being driven by the triple bottom line: social, economic, and environment, reported PTIS, adding that while it is all about Wal-Mart now, it won’t be in a few years; others will get on board. In Europe, in fact, the sustainability issue already is very strong and many large retailers are involved.

The actual workings of the scorecard were covered in great detail. The scorecard, which is free for CPGs, is connected to Wal-Mart and is submitted to them when complete. The materials data currently being used in the scorecard comes from trade associations, and as of the workshop date, was not yet verified.

Modeling software is available for suppliers, converters, and CPGS for $900. With this, they can try out different packaging parameters to see how the scores change. This software has no connection to Wal-Mart and is only for use by the individual company, though it uses metrics from the main scorecard. According to PTIS, there is no audit system in the scorecard—it’s an honor system, though some responses have to be certified. If a company has multiple sites for the same SKU, it takes an average, and no individual metric is worth more than 15%.

Attendees broke up into small groups several times to assess the scorecard and offer suggestions. Among the concerns: The system uses the distance from the converter to the end-user to judge the transportation impact, but it does not include the distance the raw materials travel to the converter. Also, some thought there should be a way to include the whole “value” of the package in regard to keeping product safe from theft and tampering, e.g., blisterpacks. As of now, this is not part of the equation.

While the scorecard is for CPG suppliers to Wal-Mart, the system includes a Virtual Trade Show, a database open to all global packaging providers of materials, package structures, and/or services. Access to this database is free for retailers, non-governmental organizations, universities, and government organizations. All others pay a $300 annual cost per supplier (2007 only) and $900 annual cost per supplier (2008 and beyond) to participate in the Virtual Trade Show.

PTIS said there is no guarantee a higher score will necessarily get a Wal-Mart supplier more business than a company with a lower score. And, they noted, no one believes price will not continue to be an issue, and no one expects Wal-Mart to drop a popular product, regardless of its score. The assumption is that other things being equal, the scorecard rating could be the deciding factor.For more on the Wal-Mart Scorecard, see Edward Boyle’s report, "Scoring the Scorecard."

Investing in Success

As part of a $13 million investment, Amcor Flexibles installed a new ten-color Rotomec gravure press at its facility in Madison, WI.

The press incorporates in-line converting operations including in-register, solvent-based coating with adhesive laminating and cold seal coating. Amcor reports its high speeds and automation allow for quick changeovers.

Other facets of the investment include a new adhesive laminating line, a new incinerator for reducing emissions and recycling energy, and the installation of a Class 100,000 Clean Room finishing area.

Rotomec | bobstgroup.com | PFFC-ASAP 327

PEOPLE

Harper Corp. of America, Charlotte, NC, adds Beth Hayes to the customer service department.

DataLase, Norcross, GA, appoints board member Trevor Bailey to the position of chairman.

Mohawk Fine Papers, Cohoes, NY, reports a number of changes: Lee Battin becomes national sales manager, western US; Paul Biesiadecki is national sales manager, eastern US; Carole Ott will serve as business development manager, western region; Desiree Kerns and Ellen Golden are business development managers, midwest and eastern regions, respectively; and Richard Schielke joins as national printer business development manager.

Paul Kling becomes North American automation sales manager at AC Technology Corp., Uxbridge, MA.

Pamarco Global Graphics, Dallas, TX, appoints Arnold Cooper sales manager, small offset products.

The Flexible Packaging Assn. (FPA), Linthicum, MD, announces the 2007 board of directors: Ilene Gordon, Alcan Packaging, chair; Peter B. Schottland, American Packaging Corp., immediate past chairman; Charles Coker Jr., Sonoco Flexible Packaging, executive vice chairman and chairman-elect; Michael Impastato, Flint Group, treasurer; Marla Donahue, FPA, president (non-voting member).

TAPPI, Norcross, GA, announces Division Awards: Mahendra R. Doshi wins the Paper and Board Div. Technical Award and Harris O. Ware prize; Tom Rodencal receives the Paper and Board Div. Leadership and Service Award; Dr. Derek Page wins the 2007 Technical Award and Richard S. Hunter Prize from the Process and Product Quality Div.; James Yarborough is named winner of the Process and Product Quality Div. Leadership and Service award.

Tracy L. Scott is VP of operations for the North and South American operations of Klöckner Pentaplast/Americas, Gordonsville, VA.