Show Preview | CPP EXPO and PRINT 13 Share a Stage

- Published: August 08, 2013, By Claudia Hine

A strategic alliance between H.A. Bruno LLC and the Graphic Arts Show Co. (GASC) will bring CPP EXPO and the every-four-year PRINT show together for the first time at McCormick Place in Chicago. The co-located shows will run September 8-12, and attendees will have one-badge access to both events. To register, click here.

A strategic alliance between H.A. Bruno LLC and the Graphic Arts Show Co. (GASC) will bring CPP EXPO and the every-four-year PRINT show together for the first time at McCormick Place in Chicago. The co-located shows will run September 8-12, and attendees will have one-badge access to both events. To register, click here.

CPP EXPO will feature suppliers of equipment, materials, and supplies of specific interest to the converting industry, including flexible packaging, folding carton/boxmaking, corrugated converting, tissue converting, and narrow web tags and labels. Although the PRINT show focuses on commercial printing, it offers exhibits of interest to package and specialty printers as well.

Among the more than 500 exhibitors on the floor of the two shows, organizers report more than half of the exhibitors will be present with products, services, and software relating to the package printing and converting industry.

“This dual exhibition of CPP EXPO and PRINT 13 provides the ideal scenario for attendees in the package printing and converting market since they will be able to see and discover all of the very latest in digital, flexo, gravure, offset, prepress, and design technologies, and products that are so vital to their customers’ brand marketing strategies,” says Leo Nadolske, president of CPP EXPO. “Attendees of either CPP EXPO or PRINT 13 will gain access to the combined offerings of both events with a full entry pass to all of the exhibits, plus be able to take advantage of a multitude of industry peer networking opportunities provided by the co-location of both exhibitions and also many other co-located events.”

CONFERENCE PROGRAM

Register now for CPP’s Conference Program, which will feature PFFC’s expert columnists offering educational sessions on topics of specific interest to converters. PFFC sessions include:

Timothy J. Walker, president, TJWalker + Assoc. and author of PFFC’s “Web Lines” column

- Did Tension Control Mess Up My Registration?

- Tuning Up Your Nipped Rollers (To Increase Profits)

- Wrinkle-Free Web Handling

- Stop Telescoping Your Rolls

- Causes and Remedies for Web Bagginess

Mark Miller, founder/CEO, Coating Tech Service and author of PFFC’s “Coating Matters” column

- Process Troubleshooting: Web Technology and Six Sigma Methodology

- Rheology/Slot Die Coating Technology

Dene Taylor, PhD, principal and founder, SPF-Inc. and author of PFFC’s “On Print” column

- Extended Gamut Printing: Please your customers and go lean too

- Finishing for Digital Printing Presses

- Digital Printing for Packaging and Labels

Kelly Robinson, PE, PhD, consulting engineer, Electrostatic Answers and author of PFFC’s “Static Beat” column

- Controlling Static in Winding Rolls and in Stacks of Sheets

- So, Should We Patent That?

Additional sessions of note:

- If Your Press Went to School, What Grade Would It Get? by Henry B. Freedman, editor, Technology Watch-Image Test Service Div.

- Dimensional Digital Decorating for Packaging by Vince Cahill, president, VCE Solutions

- Developments in Printing RFID Tags and Other Smart Packaging Solutions by Vince Cahill, president, VCE Solutions

Sun Chemical also is sponsoring speaking sessions at the show with four presentations on topics including food safety, barrier and specialty coatings, color management.

For a complete list of conference sessions, click here.

INKJET CANDY STORE

A brand new exhibit floor feature, the Inkjet Candy Store, is designed to attract those with an interest in wide format inkjet printing by offering a consolidated area to compare equipment. After touring the Inkjet Candy Store, attendees can move on to the manufacturers' booths for a deeper dive into the technologies, features, software, unique applications, substrates and inks.

A maximum of eight to 10 spaces for new equipment have been provided in the Inkjet Candy Store with exhibitors each limited to one new inkjet wide format printer. Among the exhibitors included are Epson, HP, Mutoh, and Roland DGA.

BOOTH DESCRIPTIONS

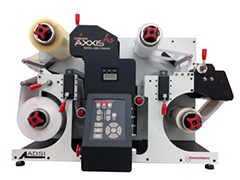

Allen Datagraph Systems (Booth 2376) will demonstrate two 2013 Must See Em Award recipients: the iTech AXXIS HS Digital Label Printer and the iTech AXXIS HD Digital Label Finisher that together comprise the iTech AXXIS HS Digital Label System, a complete turnkey tabletop digital solution.

Allen Datagraph Systems (Booth 2376) will demonstrate two 2013 Must See Em Award recipients: the iTech AXXIS HS Digital Label Printer and the iTech AXXIS HD Digital Label Finisher that together comprise the iTech AXXIS HS Digital Label System, a complete turnkey tabletop digital solution.

The printer includes an LED toner roll-to-roll printer, imaging consumer-quality labels with brilliant, durable, consistent color at 1200 dpi x 600 dpi at speeds up to 30 fpm. It delivers high definition printing with four-color stochastic screening versus traditional flexographic and laser printer based systems using halftone screening.

The finisher is able to laminate and contour cut labels of any size and shape on-demand, without a die. Print to cut registration is accomplished via the SMARTMark Optical Registration System, using the Allen DirectCut plug-in to Adobe Illustrator or Corel Draw for vector-based die lines.

Aproove SA (Booth 2644) will demonstrate the latest version of its secure online collaboration, soft proofing, and approval system for printers, brand owners, and agencies, which has received the 2013 InterTech Technology Award from Printing Industries of America. The award wlll be presented on September 8 at PRINT. The Aproove architecture offers optimized performance on Windows, Linux, and Mac environments as well as client apps for iOS, Android, and BlackBerry.

Autobond (Booth 112) will demonstrate the Mini 76 thermal film laminator, equipped with an in-line inkjet spot UV (SUV) machine and a high speed flying knife cross cutter, neither of which have been exhibited in North America before. The configuration comprises a one-sided, thermal thin film, sheetfed laminator equipped with a Heidelberg Speedmaster 74 feed-head, a highly accurate flying knife cross-cutter, and spot UV varnishing machine. Capable of producing applications with stunning gloss effects and braille-like feel, the technology uses inkjet printheads to spot print UV varnish in-line with lamination in a single pass.

Autobond (Booth 112) will demonstrate the Mini 76 thermal film laminator, equipped with an in-line inkjet spot UV (SUV) machine and a high speed flying knife cross cutter, neither of which have been exhibited in North America before. The configuration comprises a one-sided, thermal thin film, sheetfed laminator equipped with a Heidelberg Speedmaster 74 feed-head, a highly accurate flying knife cross-cutter, and spot UV varnishing machine. Capable of producing applications with stunning gloss effects and braille-like feel, the technology uses inkjet printheads to spot print UV varnish in-line with lamination in a single pass.

The flying knife cutter, available in widths of 30 in. or 41 in., is capable of running OPP, PET, and nylon. The cutter uses an arrowhead blade to physically cut the film along the under lap line at up to 200 fpm with great accuracy, leaving a clean edge. It can be adapted to run two-sided thick film applications, edge seal and flush cut, or for pressure-sensitive applications such as floor and window graphics, magnet lamination, and metallized film.

Avanti (Booth 4242) offers Avanti Slingshot, a next generation Print MIS incorporating business intelligence (CRM, dashboards, and reporting), production planning (estimating, imposition, planned purchasing, sales orders, inventory management, and scheduling), fulfillment, shipping and billing into one easy-to-use and easy-to-implement system. It is browser-based, providing organizations with the flexibility to access the system anytime on any device.

CGS (Booth 2644) will feature IC3D Suite, said to be the world's first Real-Time 3D packaging visualization, ideation, and design application, which also won a "Must See 'Em" award from GASC. The technology applies to packaging design for flexible packages, cartons, bags, and more. It uses a patented Auto Mesh Mapping process allowing labels and artwork to be placed accurately on complex packaging models in Real Time as opposed to tedious UVW mapping of texture coordinates by a third party specialist. It includes a direct link to Adobe Illustrator, allowing 2D artwork to be mapped onto 3D models as base artwork or as labels. The results are output from IC3D Suite as PDF files, hi-resolution images or as a movie for collaboration between stakeholders on computers, phones and tablets. Finished models can be 3D printed on the latest commercial 3D printers using its STL file export capability for rapid prototyping.

Colter & Peterson (Booth 3940) will introduce a 57-in. dual rotary knife precision sheeter. With an innovative, modular design and the latest technology with Siemens electronics, the fast, efficient, and durable machine can cut up to 900 fpm with a +/- 0.010 in. cutoff accuracy. It develops 57-in. tall skids and offers slitter capacity.

Colter & Peterson (Booth 3940) will introduce a 57-in. dual rotary knife precision sheeter. With an innovative, modular design and the latest technology with Siemens electronics, the fast, efficient, and durable machine can cut up to 900 fpm with a +/- 0.010 in. cutoff accuracy. It develops 57-in. tall skids and offers slitter capacity.

The Saber brand line of paper cutters will be represented with in-booth demonstrations of the new 45-in. SaberX15. A heavy-duty machine manufactured to ISO-9001 standards with cutting edge technology, this cutter offers automatic knife adjustment, Microcut 15-in. touchscreen controls, and other features.

Color Logic (Booth 5049) will show the metallic printing and special effects available with its Process Metallic Color System on a variety of substrates in exhibit booths throughout the show, including CGS-ORIS, Epson, GMG, GTI, Hewlett-Packard, Kompac, Roland DGA, and Scodix. Samples will demonstrate the system using offset lithography, flexography, digital, gravure, and screen printing, as well as wide-format UV, solvent, and latex inkjet.

DALIM SOFTWARE (BOOTH 4245) will introduce a number of major version updates of its popular workflow automation software TWIST, its customer-facing web-based production managment solution, ES, and it soft proofing application, DIALOGUE Engine.

Dover Flexo Electronics (Booth 1775) will have active demonstrations of the new communications options of the SteadyWeb 5 tension controller. Experts will be onsite throughout the show to discuss specific questions and unique challenges.

Empire Treater Rolls (Booth 1973) will show its glass steel treater rolls with knowledge experts onsite to discuss your specific questions.

Esko (Booth 4231) will have an area for demonstrations of Suite 12.1, the latest version of software solutions covering an entire range of design, workflow, and collaboration. Esko will show how its Equinox tools extend color gamuts for flexo and digital presses. Esko partner and Danaher sister company X-Rite will be on the booth showing its color management solutions and demonstrating how Esko color management works with PantoneLIVE.

A CDI 2420 digital flexo imager and a display area dedicated to Full HD Flexo also will be showcased. A high-speed Kongsberg i-XP24 finishing tabel wil be cutting samples created on a digital press.

Estimator Corp. (Booth 4546) will feature its complete MIS solution, including estimating, ordering, scheduling, production, billing, and job-costing for use for any sheetfed, web, digital, wide format, silk screen, or flexo equipment.

FFEI (Booth 1218) will launch Graphium, a modular digital UV inkjet press with high opacity digital white for the production of labels, packaging, and specialty print. Graphium combines innovative workflow, prepress, color management software, and cutting-edge head calibration technology, ensuring consistent quality through repeatable production. This guarantees a match between press and proof, aligning to color standards. Printers and converters are able to benefit from high quality, vibrant printing, with excellent adhesion, light fastness and durability.

FFEI (Booth 1218) will launch Graphium, a modular digital UV inkjet press with high opacity digital white for the production of labels, packaging, and specialty print. Graphium combines innovative workflow, prepress, color management software, and cutting-edge head calibration technology, ensuring consistent quality through repeatable production. This guarantees a match between press and proof, aligning to color standards. Printers and converters are able to benefit from high quality, vibrant printing, with excellent adhesion, light fastness and durability.

GMG (Booth 4837) will display ProductionSuite v2 (a PRINT 13 Must See Em), which is an update of the most complete production solution for wide-format printing. New features include an easy-to-use version of SmartProfiler to accurately profile any combination of printer, media, inks, etc.

GMG OpenColor is a proofing technology that precisely predicts the color appearance of printed inks, particularly "overprints"—inks printed on top of each other. This allows the previously unattainable ability to assure a proof will accurately simulate a printed result.

Goss International (Booth 2312) will exhibit under its "See Things Differently" theme, emphasizing advantages and opportunities for packaging printers. The company will present updates on the Sunday Vpak web offset press models for flexible packaging, label, and folding carton applications. They feature quick-change sleeve technology and are available in narrow and wide web widths from 20.5 in. (510 mm) to 75 in. (1905 mm).

Goss International (Booth 2312) will exhibit under its "See Things Differently" theme, emphasizing advantages and opportunities for packaging printers. The company will present updates on the Sunday Vpak web offset press models for flexible packaging, label, and folding carton applications. They feature quick-change sleeve technology and are available in narrow and wide web widths from 20.5 in. (510 mm) to 75 in. (1905 mm).

Global Graphics (Booth 958) launches Harlequin MultiRIP 10, developed specifically to enable print shops to grow out into digital print or to expand into digital marketing. It introduces new features that speed up the processing of PDF/VT and increase the rate that pages are fed to the press for significant productivity gains.

Glunz & Jensen (Booth 1963) will show the Microflex sleeve trimmer that enables customers to easily cut sleeves in correct and exact sizes. The sleeve trimmer is very simple to operate and therefore does not require any special skills. The sleeve is quickly and easily mounted on the adapter using compressed air. The correct sizes to be cut are easy to adjust as the machine is delivered with a measuring device. The double-edge titanium covered knife is made especially for this type of work and ensures a clean and quick cut through the polymer and fiberglass in the sleeve. The trimmer is delivered with a variable speed control.

Also presenting a tabletop flexo plate mounting table designed especially for the narrow web and label market. The mounting table is suitable for mounting of flexographic photopolymer plates onto sleeves up to a maximum size of 500 mm (19.68 in.) in width and 610 mm (24 in.) in repeat. This handy model is particularly suited for mounting one plate per sleeve. The microMounter allows highly productive and extremely precise mounting and registration of any flexographic printing plate by using a patented fiber optic projection to quickly pre-locate the microdots, followed by a 40x enlargement of the microdots as displayed on the cross hairs of the integrated LCD monitor.

INX Intl. Ink Co. (Booth 217) will exhibit under the theme “The FX of INX,” to show visitors technical advances that bring increased size, speed, safety, and impact to packaging and digital printing, such as UV inks and coatings that create textured feels, soft touches, pearlescent glows, high contrast glosses, and gleaming metallic finishes. For improved reproduction on wide and superwide displays, one FX station will be dedicated to alternative digital inks. Another area will feature demonstrations of Triangle MED UV LED inks, optimized for the Mimaki 3042 printer, said provide greater adhesion to multiple substrates in comparison to the OEM product.

INX plans to show the value to sheetfed printers for retrofitting their presses to LED UV. In conjunction with Air Motion Systems (AMS), PEAK LED-UV delivers new levels in high LED intensity, working distance, uniformity, durability, and ease of use, opening the door for curing innovations in offset, flexo, and digital applications. Compatible with the AMS curing unit, INXCure LED OSF process inks are 100% reactive inks that offer superior printing properties and are suitable for high-end sheetfed applications.

The NW140 UV digital narrow web press, powered by the JetINX printhead drive and ink recirculation system, will demonstrate its UV-LED cure single pass output up to 80 fpm on any label stock.

KBA North America (Booth 2321) will show the different market segments it serves, including folding carton, flexible packaging, security and digital printing, and signage/POP, on the outer perimeter of its booth. The centerpiece will be a lounge atmosphere with German beer and sausages.

KBA North America (Booth 2321) will show the different market segments it serves, including folding carton, flexible packaging, security and digital printing, and signage/POP, on the outer perimeter of its booth. The centerpiece will be a lounge atmosphere with German beer and sausages.

KBA will launch the new Rapida 164 press, dubbed the "big sister" to the Rapida 145 that was unveiled at Drupa. It features a marginally larger sheet size and higher print speed than its predecessor, the 162/162a. It reaches maximum production speed up to 16,000 sph with KBA's high-speed upgrade. The booth also will focus on its entry into high-volume digital print with the KBA RotaJET 76, an inkjet web press.

Kodak (Booth 3187) is launching KODAK PRINERGY Workflow Version 6 for prepress production, which is said to bring a new level of automation, accuracy, and efficiency to print creation, while reducing costs in the pre-planning print stage and expanding product integration across Kodak and third-party solutions. Introduces a new streamlined productivity-focused interface call Workspace.

With its at-a-glance overview of prepress production and easy-to-learn Manage, Plan and Track modules, Workspace makes it simpler for a broader set of users to drive standard sheetwork jobs to press. Workspace can be accessed from any browser and broadens the point of entry for users.

Komori America Corp. (Booth 1251) will market and sell Colter & Peterson's ancillary print finishing equipment as part of the KomoriKare program in the US. Komori will demonstrate a new C&P Saber 45-in. X15 cutter in its booth.

Mark Andy (Booth 1273) will feature its latest mid-web press, Versa Max, which is called ideal for short run film and flexible packaging applications with a minimum repeat size of 10 in. (254 mm) and best-in-industry changeover times. Its robust design offers continuous full-rated speed while purpose-built drying solutions deliver maximum productivity.

Mark Andy (Booth 1273) will feature its latest mid-web press, Versa Max, which is called ideal for short run film and flexible packaging applications with a minimum repeat size of 10 in. (254 mm) and best-in-industry changeover times. Its robust design offers continuous full-rated speed while purpose-built drying solutions deliver maximum productivity.

The Performance Series press platform reportedly features the most innovative print station and die-cutting platform designs in the industry. Available as a hands-on, interactive display, visitors are able to set up a full print station and experience first-hand the ease of use and productivity that saves valuable time.

Mark Andy VPM400 Video Plate Mounter combines heavy-duty construction and durability to produce a high quality video plate mounting technology at a cost-effective price. Innovative features such as dual cameras and a laser pointer for quick alignment offer the consumer extreme operator convenience. The VPM400 will be on display for interactive demonstrations daily.

Masterpiece Graphix (Booth 860) will exhibit in the GREENspace area of the show with materials and substrates that are compatible with almost any digital printer or press.

Masterwork Machinery Co. Ltd. (Booth 1267) will feature its full line of converting/package printing and finishing solutions including high-precision, high-speed automatic die-cutting machines, high-precision automatic platen foil stamping and die-cutting machines, high-speed folding and gluing machines, and digital quality inspections systems. The company earned two Must See 'Ems for the MK420MINI Q full automatic carton inspection machine and the MK21060STE Duopress foil stamping/die-cutting combination machine with stripping.

The Mini’s new technology removes the cumbersome human inspection process and allows the 420MINI’s high-speed CCD camera to detect the slightest deviations from the standard sample. The 420MINI Q has a highly-adjustable patented light source that can make meticulous and accurate adjustments according to the different printing processes, such as laser or holographic foil stamping. This light source, found only on MK machines, can filter the reflective light on the sheets to make the image clear and give the best detection results. The MK 420MINI offers a maximum running speed of 75,000 sheets/hour. It will take a maximum sheet size of 420mmx350mm and a minimum sheet size of 70mmx70mm.

Masterwork’s MK21060STE Duopress foil stamping/die-cutting combination machine is reported to be the world’s first and only double-station machine designed with a one-pass integrated system combining the platen through the embossing and foil stamping onto the die-cutting and stripping functions. The two-platen system boasts a maximum output speed of 6,000 sheets per hour, but because multiple passes with two platens run at one time, users realize an output of 12,000 sheets per hour. Its optimized pressure adjustment provides a better foil stamping result. Its patented design of the adjusting mechanism ensures that the two units have high register accuracy. A separate power-driven waste conveyor belt is capable of removing waste at a high speed.

Masterwork’s MK21060STE Duopress foil stamping/die-cutting combination machine is reported to be the world’s first and only double-station machine designed with a one-pass integrated system combining the platen through the embossing and foil stamping onto the die-cutting and stripping functions. The two-platen system boasts a maximum output speed of 6,000 sheets per hour, but because multiple passes with two platens run at one time, users realize an output of 12,000 sheets per hour. Its optimized pressure adjustment provides a better foil stamping result. Its patented design of the adjusting mechanism ensures that the two units have high register accuracy. A separate power-driven waste conveyor belt is capable of removing waste at a high speed.

MBO America (Booth 531) will show several innovative high-tech print finishing lines and digital technology solutions with live demonstrations.

Messe Duesseldorf (Booth 3736) will promote its worldwide program of international printing trade fairs, including drupa 2016 (to be held May 31-June 10 in Duesseldorf, Germany); All in Print China 2014 (November 14-17 in Shanghai), and Indoprint 2014 (September 3-6 in Jakarta, Indonesia). Exhibitor and visitor information, as well as hotel and travel information, will be available.

Mondi (Booth 458) will show an expanded line of high-speed inkjet papers for dye and pigment digital printing systems, which are part of the company's Green Range of eco-conscious papers. These include DNS high-speed inkjet CF (coated feel), DNS high-speed inkjet NF (natural feel), 100% recycled NAUTILUS high-speed inkjet, BIO TOP3 high-speed inkjet and DNS enhanced color inkjet, which is Mondi's first high-speed inkjet paper with a pigment-coated inkjet surface. As a pigmented paper, DNS enhanced color inkjet delivers higher color density, allowing dye inks to reach density levels comparable to pigment ink.

OKI Data Americas (Booth 4219) will debut a new category of devices featuring what it calls revolutionary color printing technologies with game-changing media handling capabilities.

PFFC | Paper, Film & Foil Converter (Booth 1581) will demonstrate its online offerings, including its interactive Buyers Guide, Coating & Laminating, Contract Slitting, and Contract Converting Services Directories. Sign up for a free subscription to E-Clips, our weekly e-mail newsletter featuring new products, videos, converting industry news, and more. Meet the staff as well as our expert columnists, who are presenting educational sessions at the CPP Conference Program.

Printing Industries of America (Booth 4855) will offer the latest book titles, best sellers, and industry resources from Printing Industries Press. Special discounted pricing will be available at the show and a different Featured Title will be showcased each day with a 50% book-of-the-day discount. Titles include Color Printing Excellence, Color Management Handbook, JDF Workflow, Lean Printing: Pathway to Success, and more.

QuadTech (Booth 2472) will exhibit under the theme of "The Power of Better" with in-line solutions and color measurement for virtually all types of packaging substrates. Color Quality Solution is reported to be the world's first in-line color and ink control for packaging presses. The solution enables automatic sharing and processing of color data between QuadTech's in-line color measurement and off-line color measurement company X-Rite. This enables a standard spectral color measurement from ink dispensing and printing stages. Comparison of printed work with the original color information begin immediately and the Color Measurement System with SpectralCam shows real time ΔE, solid density, and dot gain values via an operator touch screen.

The Color Measurement System with SpectralCam HD enables continuous, in-line monitoring of all packaging substrates, including challenging transparent, translucent, and reflective films. It accurately measures the spectral response and calculates L*a*b*, ΔE, Density and ΔDensity, and dot gain all at full press speeds.

Autotron 2600 with ClearLogic Register Guidance System is suitable for foil, film, and paper as well as for non-print processes such as die-cutting.

Rotoflex (Booth 1273) will highlight its offline finishing products including Rotoflex VLI inspection/rewinder solution, suited for film, film packaging, and other tension-sensitive materials. The VLI accommodates web widths to 28/25 in. (718 mm), making the system ideal for flexible packaging applications.

Rotoflex (Booth 1273) will highlight its offline finishing products including Rotoflex VLI inspection/rewinder solution, suited for film, film packaging, and other tension-sensitive materials. The VLI accommodates web widths to 28/25 in. (718 mm), making the system ideal for flexible packaging applications.

Rotoflex URC 2.0 Control System incorporates simplified menus and an easy-to-use interface, allowing operators to monitor all functions from a single screen. The high-security counter with built-in missing label detection gives maximum label count accuracy, and label length count measurements are precise with the error-free shaft encoder interface. The system recognizes a wide range of materials, including clear labels with a printed mark.

Scodix (Booth 1921) will launch the Scodix Ultra Digital Press, capable of producing 1,250 B2+ (21.5 x 31. in.) size sheets per hour. Press includes RSP Technology, which ensures pinpoint enhancement positioning and registration; High Impact, offers touch and feel to make print stand out; 99 GU, which delivers high levels of of gloss; and Variable Density, which allows for variable polymer thickness, all in a single pass.

Scodix (Booth 1921) will launch the Scodix Ultra Digital Press, capable of producing 1,250 B2+ (21.5 x 31. in.) size sheets per hour. Press includes RSP Technology, which ensures pinpoint enhancement positioning and registration; High Impact, offers touch and feel to make print stand out; 99 GU, which delivers high levels of of gloss; and Variable Density, which allows for variable polymer thickness, all in a single pass.

The company will exhibit an array of digital enhancement accessory production tools, including Scodix Metallic, which offers the ability to enhance print with metallic coloring by simply utilizing the CMYK color process and enhancing it with Scodix SENSE—all in a digital one-pass print process.

Scodix Rainbow is reported to be the world's first in-house digital inkjet glittering station that produces one-of-a-kind glitter solutions for cosmetics and premium packaging. Scodix Inkjet-Braille recreates standard raised Braille format and also can match visual graphics to tactile graphics that provide the opportunity to teach and communicate complex items and concepts.

The company also will show solutions for Variable Data Printing and bar coding.

SpotOn! (Booth 502) will show the latest version of its quality control software, Verify 2.5, with a new feature, Visual Match Scorecard. Verify 2.5 is a quality control tool used to improve printing consistency, increase customer satisfaction, and differentiate production quality from others in their markets. The Visual Match Scorecard functionality applied statistical probability to define an unambiguous score for comparing print-to-standard or print-to-print based on a visual match (divided into four zones) instead of pass/fail metrics and tolerances.

Techkon (Booth 4743) will showcase the newest features of all its densitometers, spectrophotometers, and color quality assurance software products.

Xante (Booth 5007) will debut the new Excelagraphix 4200 P Series wide format inkjet printing system, powered by Memjet Waterfall Printhead Technology, which delivers more than 3 billion drops of ink/second. Also, a new version of the robust and scalable iQueue workflow, which features a unique, all-in-one RIP workflow with color handling and built-in intelligence. Color, file management, and print quality controls are all engineered specifically for digital color printing. The multi-user interface and advanced features automate complex prepress tasks, help to elmininate costly mistakes, and improve digital print quality.

Also on display: the Impressia Digital Multi-Media Press, Excelagraphix L850 Digital Narrow Web Press, Ilumina 650 GS series production presses, and PlateMaker 6 total prepress system.

For a complete list of exhibitors at CPP EXPO, click here.

For a complete list of exhibitors at PRINT 13, click here.

SHOW HOURS

Sunday, September 8, 12:00 noon to 5:00 p.m.

Monday, September 9, 10:00 a.m. to 5:00 p.m.

Tuesday, September 10, 10:00 a.m. to 5:00 p.m.

Wednesday, September 11, 10:00 a.m. to 5:00 p.m.

Thursday, September 12, 10:00 a.m. to 3:00 p.m.