Show Preview | CPP EXPO & GRAPH EXPO 2014 Cover Printing & Converting Technologies

- Published: September 12, 2014, By Claudia Hine

Chicago’s McCormick Place is once again home to the upcoming CPP Converting & Package Printing Expo, which takes place September 28 through October 1. The show, managed by H.A. Bruno, Paramus, NJ, will be co-located with the GRAPH EXPO, produced by Graphic Arts Show Co., Reston, VA. Together they offer a comprehensive exhibition of digital, offset, inkjet, flexographic, gravure, and hybrid technologies, products, and services for the commercial, transactional, converting and package printing, publishing, mailing, in-plant, photo imaging, marketing, and industrial printing industries. A single pass permits entry to both events.

Chicago’s McCormick Place is once again home to the upcoming CPP Converting & Package Printing Expo, which takes place September 28 through October 1. The show, managed by H.A. Bruno, Paramus, NJ, will be co-located with the GRAPH EXPO, produced by Graphic Arts Show Co., Reston, VA. Together they offer a comprehensive exhibition of digital, offset, inkjet, flexographic, gravure, and hybrid technologies, products, and services for the commercial, transactional, converting and package printing, publishing, mailing, in-plant, photo imaging, marketing, and industrial printing industries. A single pass permits entry to both events.

More than 550 exhibitors will be housed in the South Pavilion of McCormick Place. Attendees will find innovative equipment, materials, and supplies for all segments of the converting industry.

A PLASTIC Print Pavilion will make its debut at this year’s event and will serve as a hub that bridges print with industrial manufacturing. The new pavilion is in collaboration with The Society of the Plastics Industry (SPI), producers of the National Plastics Exposition (NPE).

“We are excited to partner with GRAPH EXPO 14 on the launch of the PLASTIC Print Pavilion,” says Gene Sanders, VP of NPE. “It is amazing the diverse plastic applications that we see, touch, and use every day—everything from printed packaging and labels to the many key tags on our key chains to the enormous 3D printed applications with plastic polymers. PLASTIC Print will help GRAPH EXPO 14 attendees discover trending revenue applications to increase unique offerings along with added revenues and profits.”

PLASTIC Print will offer live demonstrations of 3D printing and PLASTIC Print exhibitors will share their expertise and guidance, one-on-one, with current customers and new prospects seeking to invest in the future.

SHOW HOURS

- Sunday, 9/28, 12:00 p.m. - 5:00 p.m.

- Monday, 9/29, 10:00 a.m. - 5:00 p.m.

- Tuesday, 9/30, 10:00 a.m. - 5:00 p.m.

- Wednesday, 10/01, 10:00 a.m. - 3:00 p.m.

Must See ’Ems

Back by popular demand are the annual “Must See ’Ems,” innovative technologies chosen by a panel of industry experts that represent the most compelling advances in 11 categories spanning the entire graphic communications industry.

For a complete list, click here.

Conference Sessions

This year’s combined show offers more than 50 seminars in 12 key industry segments covering a broad range of essential knowledge topics. PFFC’s expert columnists will be presenting 19 conferences covering web handling, coating, digital printing, static control, and more.

For a comprehensive look at PFFC-sponsored sessions, click here.

What You’ll See

Be sure to visit PFFC in the CPP Pavilion at Booth 4526. To see the floor plan, click here. Here is a sneak peek at some of the exhibitor booths:

Brandtjen and Kluge Inc. (Booth 3617) will showcase laser converting technology with strategic partner LasX. A complex double-tuck folding carton will be laser cut, scored and etched. Company will exhibit the Kluge EHD Series press, which will be configured to fol stamp two separate carton blanks simultaneously and will be equipped with the new adjustable impression feature that reduces set up and makeready ties. Also showing new features on the Kluge ComFold folder/gluer, which will complete the final converting process of a laser cut and foil stamped folding carton.

Colter & Peterson (Booth 3617) will offer two new paper-cutting systems that memorize the cutting sequences instantly, and the backgauge will automatically position itself to deliver a precise cut within 1/64 in. Microcut COLOR WS guides the correct position movement faster and more accurately using a computer guidance system. The 8-in.-wide format touch screen display helps the operator with fast and simple set-up. Microtrack II is a cost effective, digital display and programming guide that uses a microprocessor-based unit to increase the accuracy and productivity of manually operated paper cutters. User-friendly Manual, Program, and Automatic options provide a visual alert to make the operator aware of when the backgauge is properly positioned.

DMS (Booth 4815) will show hot stamp equipment and quality embossing hot stamp tooling.

EFI (Booth 1902) will featured its 11 Must See ’Ems awards, the most ever presented to one company. They include EFI CRM for Monarch ERP and IQuote (sales and order entry), EFI Fiery Color Profiler Suite, version 4.6—Express Profiler (color management and quality control); EFI Enterprise Automated Workflow (management systems); and EFI Fiery Digital Embossing (The Future of Print).

Empire Rollers & Coatings (Booth 4917) will show examples and provide details about how its coatings and rollers can dramatically change your productivity levels. In the Presentation Theater on September 30 at 11:30, the company will share features and benefits of its Glassteel product and how it can improve efficiency.

Enfocus (Booth 535) will show its full suite of software, including the Must See ’Ems winner Enfocus Switch, Update 2; the new PitStop Font Fix; the Connect 12 product family; and the PitStop Pro PDF preflight and editing solution. Customers' most-requested features have been included in the new Switch 12 Update 2, with added color identification of folders and connections topping the list. This feature improves usability, allowing users to clearly distinguish between input and network folders, and between different connections. As a result, Switch's more complex workflows can be deciphered, even at scaled down sizes such as those on laptops.

Epson (Booth 1243) will be introducing a new SpectroProofer in-line spectrophotometer for its 17-, 24-, and 44-in. Epson Stylus Pro printers that will provide automated color management and verification-related tasks for a variety of proofing applications.

Fujifilm North America Corp., Graphic Systems Div. (Booth 3213) will preview new products including live workflow and software demonstrations of XMF, XMF Remote, ColorPath, Hybrid Packz, and Metrix, along with highlights focusing on innovative solutions for production inkjet, wide format, and label and packaging.

GMG (Booth 648) unveils a new version of the GMG ColorProof software along with the full range of GMG color management solutions. These include GMG OpenColor for the packaging market, ColorMaster, which keeps an image in a master color space until it is needed, and GMG CoZone, a producton system based in the cloud.

Goss International (Booth 1257) will show the Goss Sunday Vpak press for cost-effective short-run packaging applications. Recently announced as a recipient of a 2014 InterTech Technology Award, the Sunday Vpak press system features quick-change sleeve technology, delivering outstanding quality and fast job changeovers for board and film substrates. It is available in web widths of 20.5 in. (520 mm) up to 75 in. (1905 mm) and runs at speeds up to 1500 fpm (7.6 meters/second). Finishing and other printing processes, including flexo, gravure, and digital stations, also can be added to customize inline production.

Highcon (Booth 1262) is launching the Highcon Euclid II series of digital cutting and creasing machines and will conduct demos on the Highcon Euclid II+ machine. It includes an Integrated Digital Stripping Unit that automatically removes the waste from the smallest internal cutouts, eliminating the need to buy, setup, or store a separate stripping tool.

Highcon will be digitally cutting and creasing folding carton packages printed on the Xeikon 3500 digital press on the Highcon Euclid.

Highcon has signed an OEM agreement for the Esko CAD Digital Front End (DFE) software as a complement to its Euclid digital cutting and creasing machine. Highcon will distribute, install, and support the Esko CAD Digital Front End (DFE) software as complement to the 2014 MUST SEE' EMS award-winning Highcon Euclid. The software converts packaging structures to the finishing format required by the Euclid, which receives its CAD cutting and creasing information from ArtiosCAD prepared or converted DFX files. With the new OEM agreement, the Highcon Euclid now offers an on-board software tool, the Highcon Light Editor, that allows Euclid operators to take advantage of the benefits of digital technology by editing crease and cut lines in the structural design of the job at the point of production, including the ability to incorporate last-minute changes. It also enables optimizing of nicks by increasing or decreasing their size or adding or removing them, and adding, removing, or editing stripping lines.

HP (Booth 1913) will demonstrate digital printing technology.

INX International Ink (Booth 3813) will introduce a new Troubleshooting Guide App as well as the debut of web site initiatives INXDaily and INXTV.

KBA North America (Booth 213) will be focused on the packaging industry. KBA is now the exclusive distributor for Flexotecnica’s flexible packaging presses in North America. KBA-Flexotecnica develops, builds, distributes, and services central-impression flexographic presses for printing on flexible packaging materials. The centerpiece of the booth will be a comfortable lounge atmosphere with German beer and pretzels. On the outer perimeter of the booth will be 10 free standing walls showing the different market segments that KBA serves, including commercial printing, folding carton packaging, flexible packaging, metal decorating, newspaper, plastic cards, security printing, digital printing, signage/ POP, and service and support. The company also will reveal its newest RotaJET L Series digital inkjet press for high-volume printing. Can be optimally configured to suit the respective market and industry environment due to is modular design that can be retrofitted with future printhead generations.

Mark Andy (Booth 4213) will be featuring reliable, productive solutions designed to increase profitability. Offering a broad range of products and services that maximize uptime and optimize workflow efficiency. As a Total Solutions Partner, company offers complete support of your printing operation. Will offer live demonstrations of equipment designed to enhance workflow efficiencies for flexo, digital, and offset.

Masterwork USA (Booth 3802) will display its MK21060SER Duopress automatic platen foil stamping and die-cutting machine with stripping and MK420 Mini Q carton inspection machine. Has the ability to foil, emboss, die-cut, strip, blank, and handle product collection at 12,000 impressions/hr, all with one operator. The MK420 MINI Q high-speed, high-precision carton inspection machine allows a graphic arts firm to increase production capacity, reduce costs, and carry out 100% on-line inspections throughout 24 hr of uninterrupted operation.

Messe Dusseldorf (Booth 3643) will promote drupa 2016 and All in Print China 2014. Exhibitor and visitor information will be available, including applications for the U.S. Pavilion. Brochures about hotel and travel arrangements for the show also will be offered. The drupa 2016 exhibit categories are now divided into six main segments (formerly seven): pre-press/print; pre-media/multichannel; post press/converting/package printing; future technologies; materials; and equipment/ services/infrastructure.

MGI (Booth 3013) will demonstrate the JETvarnish 3D “T2” (Twin Head) UV spot coater and iFOIL module duo for digital embossing and hot foil stamping.

Mohawk (Booth 3240) will launch a line of inkjet substrates, introducing a unique surface technology to so synthetic materials specifically designed for emerging Memjet-class wide format inkjet printers. New products include Mohawk Inkjet DuPont Tyvek (waterfast matte inkjet receptive coating); Mohawk Inkjet Polyester Press Sensitive Permanent Adhesive (aqueous matte coated polyester); Mohawk Inkjet Matte Backlit Film (aqueous matte coated polyester backlit display film); and Mohawk Inkjet Textured Lightblock Film (banner lightblock film).

Muller Martini (Booth 1344) is showcasing its VSOP (variable sleeve offset printing) web press technology using a static replica module of a VSOP Print Tower that simulates sleeve changes to show how easy and fast it is to start a new job. The company’s mid- and narrow-web offset presses—the VSOP, Alprinta, and Concepta—offer impressive versatility in offset, flexo, gravure, digital, and screen printing, as well as various processing and finishing modules. With both the VSOP and Alprinta-V, size changes are made by exchanging lightweight sleeves, whether carbon-fiber and/or aluminum cylinders, instead of entire printing inserts.

OKI Data Americas (Booth 4231) will introduce the C711DW high quality digital color web press. Together with the HS711DLF, these devices create full color finished labels on-demand and with ease, incorporating digital die-cutting and film lamination to deliver a complete, cost-effective, digital label printing production system. The press utilizes OKI label management software from HYBRID software as a front-end solution plus Proactive server and Harlequin raster image processor. It prints at up to 25 fpm in continuous feed mode and handles a variety of media.

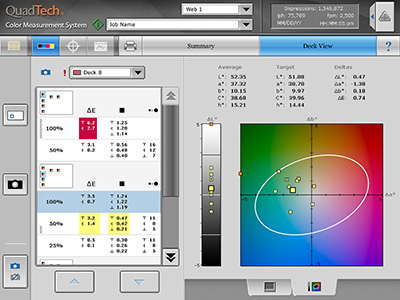

QuadTech (Booth 3740) will present its in-line color measurement and ink control system for packaging presses. QuadTech Color Quality Solution, utilizing the Color Measurement System with SpectralCam, enables automatic sharing and processing of color data between in-line color measurement and off-line color measurement industry leaders. Maintaining color quality throughout a print run provides new levels of color accuracy and assurance to converters and brand managers that color specifications have been met. The QuadTech inspection System with SpectralCam provides 100% defect inspection and true spectral color measurement, enabling accurate, high quality color packaging The QuadTech Web Viewing System can be used as a standalone system or in conjunction with the Inspection System, for real-time digital viewing of the moving web and optimum error detection.

Ryobi MHI and Graphic Systems North America (Booth 4404) will provide demonstrations of the five-color, 8-up RYOBI 925 press with LED-UV instant curing (a Must See ’Em award winner), along with full overviews of the 6-up RYOBI 750 series Packaging Edition press, and Ryobi’s UV casting and foiling system. GSNA will spotlight the advantages of the 6-up RYOBI 750 series Packaging Edition press, including six-minute makereadies, heavy-duty feeders, specialized transfer drums, inking systems, fully automatic plate changing and highly stable delivery piling. This specially equipped press runs up to 31-pt board for folding cartons and other applications.

Schober USA (Booth 1317) will feature Rotary Die-Cutting Technology especially designed for converting of digital or conventionally printed film and foil, laminates, coated paper laminates, and composite materials. The Spider high-speed programmable robotic stacking and counting system combines acceleration, velocity, and precision at speeds of up to 50 m/min (164 fpm) – allowing stacking of various types of products within the same print image. Ideal for today’s digitally printed in-mold labels; this technology allows nested product configurations with a combination of large/long and small products. The RSM-Digi/VS is ideal for use with OPP, PE, PS, PET, and more. Technology is available with web widths to 850 mm (33 in.) and die-cutting repeat of 1.220 mm (48 in.). A 100% product inspection system with defective product discharge is available. In addition to the robotic Spider delivery, other proven stacking/delivery devices available include “M” stack for short runs, “S” stack for longer runs, “SM” for awkward products, and “SMA” a fully automated solution.

Scodix (Booth 2241) will announce new products and new applications for its SENSE digital print differentiation tools. Offers shelf appeal for all folding carton printers and converters. The company will introduce the Scodix Ultra Pro press , which offers Automatic Multi Tanks and a Multi Polymer Switching System with the ability to use different polymers on the same press. Features Scodix Spot, a polmer that produces a spot varnish for short runs. It digitally recreates the effect of traditional flat varnishes without the setup time or mess. The patent-pending Scodix Ultra Twin-Tray media handling system conveys sheets under the fixed array of inkjet UV inkheads in a single pass.

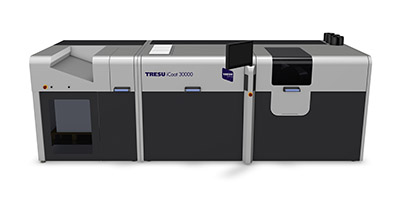

TRESU Group (Booth 1913) will exhibit its iCoat system for digital sheetfed folding carton printing lines at the HP Booth. The system has been adapted especially for HP Indigo 10000 and HP Indigo 30000 presses. Together, the TRESU and HP Indigo systems offer a complete folding carton production line - for printing, full surface or selective coating, and stacking. Offset-equivalent finishing effects are possible, with industry-standard UV or aqueous varnishes.

TS Converting Equipment (Booth 4227)—co-exhibiting with sister company Compact Foilers Ltd., a manufacturer of a module for in-line foiling on offset printing presses—will be displaying the latest range of Elite Cameron core cutters, slitter/rewinders, coating and laminating machines, and their ancillary product range, which includes differential rewind shafts and automatic knife setting systems. The CW range of compact, low-cost slitters suit most applications, are built to individual specifications, and are normally available on a short delivery. Information on the New CW800 clean slitter will be available for customers that require a clean web for medical, print, and food packaging applications. This overhead feed machine is equipped with a double-sided web cleaner, automatic reel ejection, laser core, and auto knife setting with blade cleaning. The HM range of hot melt coaters with in-line coat weight measurement, corona treating, and slitting are designed for all types of adhesive tapes and laminates also will be displayed.

Valco Melton (Booth 3655) will exhibit its CHOICE all-electric hot melt system. Featuring EcoStitch technology, the user can customize bead size and pattern, making it ideal for tabbing, inserting, and product attachment. Also displaying hot and cold carton gluing and inspection technology.

For a complete list of exhibitors, click here.