TRESU to Highlight Ink Supply System at Labelexpo

- Published: August 26, 2014

KOLDING, DENMARK | TRESU Group the global supplier of flexo technology, will present ancillary products said to improve ink flow at Labelexpo Americas 2014, September 9–11, at the Donald E. Stephens Convention Center in Rosemont, IL. Highlights will include ink supply systems, chambered doctor blade systems, and plate cleaners.

The F10 iCon ink supply system automates ink pressure, viscosity, and temperature control in flexo presses, reportedly ensuring a constant, accurate ink density on the printed substrate and preventing air from contaminating the ink chamber.

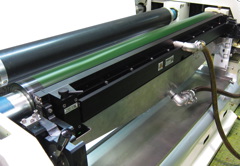

Sealed, pressure-controlled chambered doctor blade systems enable direct, bubble-free transfer of ink/coating to the anilox cells. This ensures a clean, blister-free printed image with fast drying characteristics, better reflection, and higher gloss values on paper or film.

Chambered doctor blade systems include the FlexiPrint IMW E-Line for web widths p to 1,800 mm (70.8 in.) and speeds to 500 mpm 1,640 fpm); and the closed-cassette FlexiPrint reservoir, which needs no pump and operates at press speeds to 300 mpm (984 fpm). The E-Line system, including clamp, allows for safe blade changeover in less than two minutes. Company’s patented Rubber Seal System is said to ensure an airtight closure, eliminating the chance of leakage and allowing long-term storage of ink.