Automatic Cleaning Equipment Saves Money for Trisan

- Published: September 04, 2018

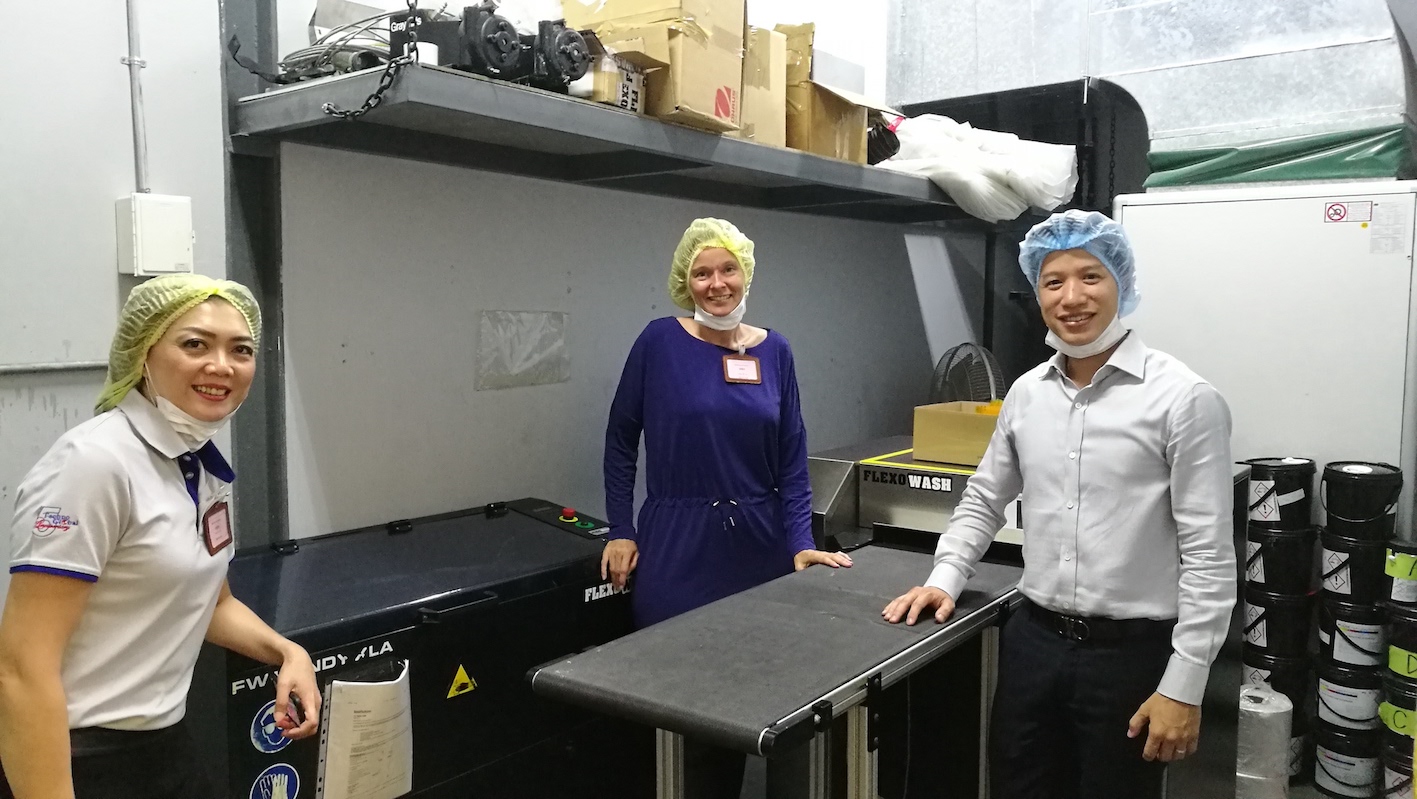

Trisan has moved to flexo production with two Nilpeter and one Omet machine. To manage the extra production capacity and higher quality labels now being produced by its 50 employees, the company decided to invest in Flexo Wash cleaning equipment.

Trisan has moved to flexo production with two Nilpeter and one Omet machine. To manage the extra production capacity and higher quality labels now being produced by its 50 employees, the company decided to invest in Flexo Wash cleaning equipment.

This first installation came about because of Trisan’s longstanding relationship with Techno Global Graphics, the Flexo Wash agent in Thailand. TGG is based close to the Trisan plant and has established a close bond of trust with the company. When Trisan saw the need for a Plate Washer, it invested in more Flexo Wash technology.

“Automation is important in a competitive market and that is one of the reasons why we invested in cleaning equipment. We need the same output but faster,” said Piyapong Wongvorakul, managing director at Trisan.

Currently, Trisan has a 20-30 minute change over time, but the target is 10 minutes, and one way to get there is knowing that the aniloxes, plates, and parts are 100 percent clean. The first Flexo Wash cleaning system at Trisan was an anilox cleaner.

“Cleaning aniloxes manually takes too long, and if not done properly it results in ink contamination. Since we installed the anilox cleaner we have seen no ink contamination, and because the machine does the job, we can supply our customers with better and consistent quality print,” explained Wongvorakul.

Now anilox cleaning takes only three minutes and there is no damage to the expensive rolls.

“Since installing the Plate Washer we have seen a reduction in damaged plates, which has been a huge cost saving. Where previously 12-15 plates were damaged each week, this figure is now one or two, and those are not caused by cleaning,” continued Wongvorakul.

Following the recent Labelexpo in Bangkok, Trisan decided to invest in a Parts Washer. It is the first Parts Washer that Flexo Wash/TGG will install, and the target is that the installation will reduce the manpower involved in cleaning at Trisan’s plant.

“The latest Flexo Wash machine allows us to clean several parts at the same time, which means that cleaning is faster, and it allows the highly skilled press operators to focus on printing instead of cleaning. For us, it is clear proof that automation is the way to go,” he concluded.