Static Control for Labels

- Published: September 28, 2020

Labels are prone to static failures because cut sheets are more sensitive to static than continuous webs.

By Kelly Robinson, Contributing Writer

Static causes headaches in label operations. Often, as long as the material is a continuous web, everything is fine. Then, when we cut or punch the material, the sheets cling and stacks block. Labels with pressure sensitive adhesives (PSAs) often stick or cling when they are peeled from the release liner. Static can also cause release failures where labels stick to the release liners causing jabs that can such down the line.

To prevent these problems, we need to understand why labels are so prone to static failures. Table 1 summarizes five reasons why labels are prone to static problems.

Table 1: Labels are prone to static problems

|

# |

Reason |

|

1. |

Labels are cut sheets that are sensitive to static. |

|

2. |

Balanced charges block stacks. |

|

3. |

Static spots from sparking cause sticking. |

|

4. |

Sparking damages release liners. |

|

5. |

Charges separated by peeling cause sticking. |

- Thin labels are mechanically weak. First, let’s recall a bit of structural engineering. The deflection dBeam of a cantilevered beam varies inversely with the cube of beam thickness; . So, when we use a thinner material, our labels bend easier. Decreasing label thickness from 1 mil to 1/2 mil increases bending from static by 8X. Wow! A simple cost reduction decision to use thinner material increases sensitivity to static by 8X.

Perform a static survey to measure static performance. Running webs and sheets thinner than 1 mil (0.001 in. or ~ 25 mm) requires lower electric fields. Usually, electric fields less than ±5 KV/in are OK. For materials less than 1 mil, keep electric fields less than ±2.5 KV/in.

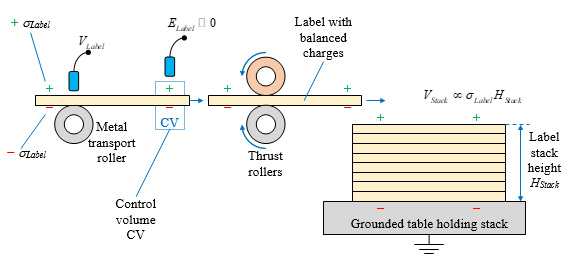

Figure 2: The stack voltage VStack increases with stack height HStack.

- Balanced charges block stacks. Static problems caused by balanced charges are difficult to diagnose because fieldmeters do not see balanced charges. The fieldmeter in Figure 2 responds to all of the static charges inside the control volume CV. With balanced charges, there are equal numbers of positive and negative charges. So, the fieldmeter reads zero. With a zero reading, we think that the labels entering the stack have no static. Yet, the balanced charges cause the voltage VStack to increase as the stack builds. The voltage VStack is proportional to the static charge density sLabel and the stack height HStack; . When there is too much static, the stack blocks when we touch the top. Taller stacks block more easily. And, once the stack is formed, it is devilishly difficult to prevent blocking.

To prevent blocking, we must minimize static charges on labels entering the stack. Certainly, measure the electric field ELabel using an electrostatic fieldmeter before entering the thrust rollers in Figure 2. The reading should be less than ±2.5 kV/in. And, measure the voltage VLabel on labels using an electrostatic voltmeter over a metal transport roller. The reading should be less than ±10 V per mil of thickness. So, for a 1 mil (0.001 inch) thick material, reading VLabel should be less than ±10 V. If either ELabel or VLabel are too big, improve static control upstream of the readings.

- Static spots from sparking cause sticking. When the electric field is too big, sparks happen. Sparks are like miniature dissipaters. Each spark deposits a spot of opposite charge on the material. If our label has high negative static (ELabel>±15 KV/in), sparks deposit spots of positive charge. These spots of charge can cause sticking, jamming, and blocking.

Prevent sparking by keeping the electric fields ELabel less than ±5 KV/in, ELabel < ±5 KV/in along the entire material flow upstream of the sheeter. Complete a static survey to verify that static control is good.

- Sparking damages release liners. Static causes two additional problems on labels with pressure sensitive adhesives (PSAs). Sparking after coating release liner can damage the silicone release coating. The coating is typically very thin making it rather sensitive to sparks that cause holes in the coating.

Prevent sparking during the production of the release liner by keeping the electric fields ELabel less than ±5 KV/in, ELabel < ±5 KV/in along the material flow downstream of the silicone coater.

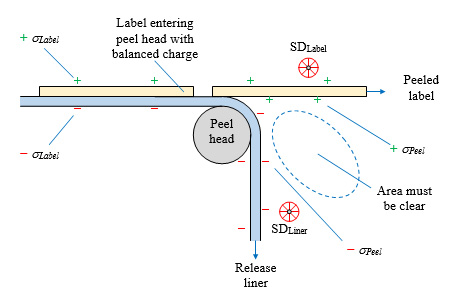

Figure 3: Peeling separates charges both from balanced charges and from tribocharging.

- Charges separated by peeling cause sticking. Peeling labels from the release liner separates charge in two ways; and from separating balanced charges and from tribocharging. Commonly, labels entering the peel head in Figure 3 have balanced charges. The labels often have positive charges indicated by + sLabel. The release liner has negative charges indicated by − sLabel. Exiting the peel head, the positive charges + sLabel remain on the labels. The release liner exits the peel head with negative charges − sLabel.

Tribocharging occurs when two chemically different materials touch and separate. One material separates with positive static. The other separates with negative static. Tribocharging is always equal and opposite. Silicone release liners typically separate with negative charge indicated in Figure 3 by − sPeel. The PSA on the label usually separates with positive charge indicated by + sPeel. The charges + sPeel and − sPeel are on the surfaces that were previously in contact.

The charges on the labels both from separated balanced charges and tribocharging cause sticking, label jams, and static cling. The charges on the release liner cause high static on the winding roll of empty liner.

To prevent these problems, first minimize balanced charges on the labels entering the peel head just as described for labels entering a stacker. Measure the electric field ELabel using an electrostatic fieldmeter before entering the peel head. The reading should be less than ±5.0 kV/in. And, measure the voltage VLabel on material a metal transport roller. The reading should be less than ±10 V per mil of thickness. So, for a 2 mil (0.002 inch) thick material, reading VLabel should be less than ±20 V. If either ELabel or VLabel are too big, improve static control upstream of the readings.

Dissipate tribocharging from peeling using static dissipators. Passive dissipators such as static brushes, tinsel strands, ionizing cords or ionizing rods dissipates enough static to suppress sparks and to prevent static cling. Usually, the area near the peel head in Figure 3 must be clear so operators can thread the machine and clean the peel head. So, no static dissipators should be located in this area.

Dissipate static on the labels exiting the peel head by locating static dissipator SDLabel facing the side of the label with no adhesive. In this location, the dissipator with form balanced charges. While forming balanced charges is normally bad, it is OK in this application. The balanced charges on the label will prevent static cling and label jams.

Dissipate static on the release line exiting the peel head by locating static dissipator SDLiner facing the side of the release liner that touched the labels. In this location, the dissipator will not form balanced charges on the release liner. When the liner is wound, static on the winding roll is minimized by locating SDLiner facing the correct side of the liner.

Our over-arching static control goal is to prevent static blocking on stacks and label jams. We also need to prevent sparks during production of the release liner. Minimizing balanced charges is required to prevent blocking. To do this, we need to practice good static control along the material flow all the way from the unwinding roll to the stacker.

About the Author

Kelly Robinson, PE, Ph.D., is the owner of Electrostatic Answer, an engineering consulting company dedicated to eliminating injury and waste from static electricity. He can be reached directly at This email address is being protected from spambots. You need JavaScript enabled to view it..