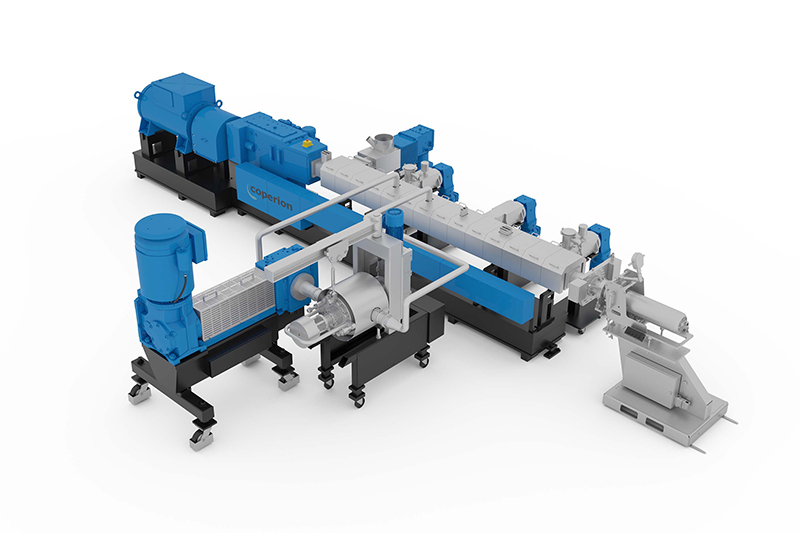

New ZSK FilCo Filtration Compounder for Higher Product Quality and Reduced Energy Consumption in PCR and Polymer Recycling

- Published: January 10, 2024

For recycling of post-consumer recyclate (PCR) or any highly contaminated polymer, Coperion has developed the innovative ZSK FilCo filtration compounder that allows filtration and compounding in a single production step.

With the new ZSK FilCo system, waste plastic is fed into a ZSK twin screw extruder, where it is melted, homogenized and devolatilized. The melt is then fed through a filter to remove all contaminants before it is fed back into the same ZSK extruder to be compounded with reinforcing materials or fillers.

Compared to the two-step production lines that have been the norm until now, Coperion’s new ZSK FilCo is distinguished by a markedly more streamlined equipment set-up. Energy consumption and emissions for the extrusion process are reduced by more than 50 percent. Moreover, the ZSK FilCo is able to achieve a significantly higher product quality. Recompounds can be produced much faster and Coperion K-Tron gravimetric feeders ensure the high-accuracy incorporation of additives for an optimal result.

Filtration and Compounding in Single Production System

In conventional recycling plants, PCR and contaminated polymers must first be melted using a single or twin screw extruder, then filtered and pelletized thereafter. For plastics upcycling purposes the filtered recompounds are then fed into a separate twin screw extruder where they are again melted and compounded with the aid of additives, reinforcing materials and fillers before finally being pelletized. In this production set-up, energy for melting must be introduced twice. Along with high energy consumption, the recyclate is subjected to high thermal stress which in turn results in increased degradation, shortening of polymer chains and thus a reduction in product quality.

The new ZSK FilCo makes it possible to melt, filter, compound and pelletize recyclate in a single production system. Waste plastic is fed into the ZSK extruder in the form of regrind, fiber pellets, film flakes or agglomerate and is melted, homogenized, and devolatilized there, together with all its components (all polymers, PE, PP, PA, PS, PC/ABS, etc.). Next the melt is fed through an integrated filter that removes all contaminants. Reintroduction into the ZSK extruder process section follows, where reinforcing materials such as glass, wood, and carbon fibers, or fillers such as talc, CaCO3 or ground PEX are added, after which the recompound is pelletized.

The ZSK FilCo’s space requirement is comparatively low. All product streams are added gravimetrically to the process with no fluctuations. The recyclate needs to be melted only once. The ZSK FilCo thus consistently achieves a higher product quality than multi-part systems that have been typically used for this recycling process.

Moreover, energy consumption and emissions for the extrusion process are markedly reduced with the new solution. Thanks to the twin screw extruder’s high mechanical energy input, the melting process is more energy efficient than with a single screw extruder. In addition, the second melting process for compounding is completely eliminated in the ZSK FilCo solution and pelletizing of the intermediate compounds is also omitted.

Marina Matta, Team Leader Process Technology Recycling at Coperion, is very proud of this newest Coperion development: “The ZSK FilCo is one more result of our targeted efforts to optimize the recycling of plastics and to further increase the sustainability of the overall process. The ZSK FilCo’s excellent energy economy and the high end product quality that it achieves are important benefits that will once again make PCR and polymer recycling a bit more attractive for many companies.”