Static Control for Corona Treaters

- Published: December 03, 2020

Kelly Robinson, Contributing Writer

Corona treaters can deposit very large amounts of static on web.

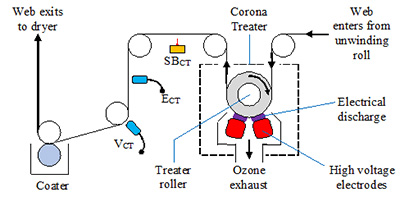

Figure 1: The corona treatment before coating improves wettability and increases adhesion.

The corona treater in Figure 1 is a chemical reactor that uses an electrical discharge to modify the chemistry of the treated surface. Treaters are often used before lamination to improve adhesion and before coating to improve wettability and adhesion. Corona treaters incorporate oxygen species into the treated surface. Atmospheric pressure plasma treaters can incorporate nitrogen and other chemical species. These chemical changes improve wettability and increase adhesion.

The corona treater in Figure 1 produces two, unwanted by-products; ozone in the air and static on the web. After we neutralize the static, the treated surface will still have the chemical modifications that provide the improved wettability and higher adhesion.

Table 1: Corona Treater Components

|

# |

Component |

Function |

|

1. |

HV Electrodes |

Provide high voltage |

|

2. |

Power Supply |

Provides electrical power |

|

3. |

Treater Roller |

Provide ground for discharge, and |

|

4. |

Ozone Exhaust |

Removes ozone. |

Table 1 summarizes the functions of the four key components of a corona treater.

- High Voltage Electrodes – A corona treater in Figure 1 has two electrodes that provide the high voltage needed to form the electrical discharge. The high voltage (7 – 15 KV) at roughly audio frequency (5 – 30 KHz) forms an electrical discharge between the electrodes and the nearby treater roller. The electrodes surfaces may be bare metal or ceramic.

- Power Supply – A power supply (not shown in Figure 1) converts 60 Hz electrical power into the high frequency, high voltage power needed by the corona treater. These power supplies are designed to deliver large amounts of power (5 – 25 KW). A typical, industrial scale, corona treater consumes about as much power as a residential house (see Static Beat: Corona Treaters & Ionizers Compared).

- Treater Roller – The treater roller serves two important functions. It is the ground for the energetic, electrical discharge that drives the valuable chemistry. And, the treater roller conveys the web through the energetic electrical discharge. The surface of the treater roller may be either bare metal or be an insulating material such as rubber or ceramic. Either the electrode surface or the treater roller surface must be insulating so that the energetic, electrical discharge is uniform rather than being an electrical arc.

- Ozone Exhaust – The electrical discharge in a corona treater is chemically active. This discharge drives the chemical reactions on the web surface that promote wettability and improve adhesion. This chemically active discharge also forms ozone and oxides of nitrogen that must be removed. The ozone exhaust system removes these unwanted by-products.

Another unwanted by-product of corona treatment is static charge on the web. I first thought that static from a corona treater should always be negative because electrons move faster through air than positive ions. However, I have measured both negative static and positive static exiting corona treaters. And, the magnitude can be very low or very high. So, we must be ready to dissipate large amounts of static of either polarity. This is an update of my earlier column (see: Static Beat | Control Static at the Corona Treater).

When the treater is operating properly, the static will be on the treated surface because the charge comes from the electrical discharge. When the web loses contact with the treater roller, backside treatment can deposit static charges on the untreated web surface. Backside treatment occurs when the web is baggy or at high speeds when air gets under the web. When we solve these problems, the static is all on the treated surface.

The best practice is to install powered static bar SBCT in Figure 1 on the web exiting the corona treater facing the treated surface (see Static Beat | Side Matters). While a passive static dissipator such as a tinsel strand may be used, I recommend using a powered static bar so that the web entering the coater is as charge-free as possible. Passive static dissipators always leave a low level of static on the web (see Static Beat | How Do Passive Dissipators Neutralize Static?).

Take two static readings to verify that static is well controlled on the web exiting the corona treater before entering the coater. Use an electrostatic fieldmeter (see Static Beat | Assess Static Risks Using Electric Fields) to measure ECT in Figure 1 on a web span exiting powered static bar SBCT (see Static Beat | ‘GeeZE’ Rules for Static Readings). Exiting a powered static bar, reading ECT should not exceed ±2 KV/in.

Use an electrostatic voltmeter (see Static Beat: Using Electrostatic Voltmeters) to measure VCT in Figure 1 when the web exiting the corona treater is wrapped on a grounded, metal idler roller such as a hard-coated aluminum idler roller. While I have shown VCT in Figure 1 being taken on the treated surface, it is OK to take reading VCT on the back, untreated surface, if this is safer or more convenient. Reading VCT should not exceed ±10 V/mil (±0.4 V/mm) of web thickness. For example, for a 2 mil (50 mm) thick web, reading VCT should not exceed ±20 V.

Corona treaters can deposit large amounts of static on treated surfaces. This static is an unwanted by-product of treatment. Dissipate static on the web from corona treaters using a powered static bar installed on a web exiting the corona treater facing the treated surface.

About the Author

Kelly Robinson, PE, Ph.D., is the owner of Electrostatic Answer, an engineering consulting company dedicated to eliminating injury and waste from static electricity. He can be reached directly at Kelly.Robinson@ElectrostaticAnswers.com.