Diagnose Static Problems With A Handheld Static Meter

- Published: June 15, 2021

Kelly Robinson, PE, PhD

Electrostatic Answers

Handheld fieldmeters are our workhorse tools for solving static problems.

Handheld static meters are our most important instruments for diagnosing and solving static problems. First, let’s take a look at what handheld static meters measure. Then, we’ll use our meter to diagnose and solve a static problem.

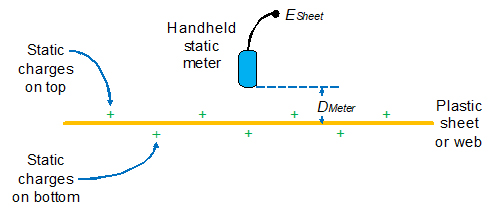

Figure 1: Hold the meter distance DMeter from the charged sheet or web

The handheld static meter in Figure 1 responds to the number of electrical charges on the plastic sheet or web. The meter displays the electric field ESheet caused by the charges. Most static meters are calibrated at a specific measurement distance DMeter recommended by the vendor. Read the directions to learn the calibration distance. For many meters, the calibration distance is 1 inch.

The display often has units of “KV” or kilovolts. So, you must divide the displayed value by the calibration distance DMeter to get the electric field. This is important when you compare readings taken with different meters.

For example, if the calibration distance is 1 inch and the meter reads “+5.0 KV,” the electric field is found in (1) to be +5.0 KV/in.

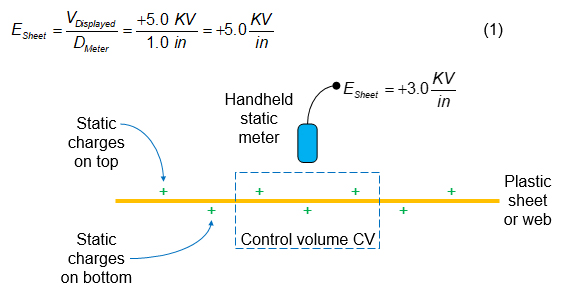

Figure 2: The static meter responds to all of the charges in control volume CV.

The static meter responds to charges on both the top and on the bottom of the web. To help me take readings, I do this “mental exercise.” In my mind’s eye, I draw a control volume in front of the static meter in Figure 2 around the plastic sheet or web. The static meter responds to all of the charges inside the control volume. Since there are three positive charges inside the control volume, the meter reads +3.0 KV.

Notice that some of the charges are on the top and some are on the bottom. The meter responds to all of the charges on both sides. So, we can take static reading from either side. We’ll get the same reading from either side. This is good because we can pick whichever side is safer and easier to measure. There is no need to measure both sides.

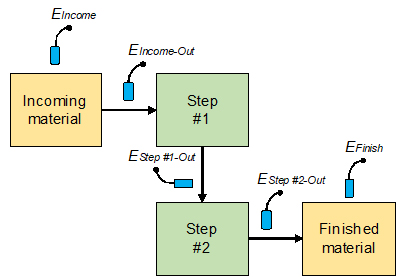

Figure 3: Take static readings along the material flow through the process.

Now, let’s solve the static problem. Suppose the process in Figure 3 has high static on finished material that causes a problem. Of course, we should measure the static level EFinish to see how much static is causing the problem.

To solve the problem, write down the static readings along the material flow in Figure 3 beginning with the incoming materials, exiting each process step, and finishing with a reading on the finished material. Look for high static readings. High readings indicate static problems. And, look for big changes from one reading to the next. These changes in readings indicate sources of static in the process. Finding the sources is the key to solving the problem.

Suppose that EIncome in Figure 3 is too high. The static problem may be caused by high static on incoming materials from your supplier. Solve this problem by working with your supplier.

If EIncome looks OK, then look at EIncome-Out. If EIncome-out is high, then there is something about how we handle incoming material causing high static. Focus on reducing static in how we handle incoming materials, or dissipate static on the material entering the process. Many good static dissipators are commercially available.

If EIncome-out is low, then look at EStep #1-out. If EStep #1-out is high, then there is something going on in process Step #1 causing high static. Focus on reducing static in process Step #1, or dissipate static on material exiting Step #1.

If EStep #1-out is low, then look at EStep #2-out. If EStep #2-out is high, then there is something going on in process Step #2 causing high static. Focus on reducing static in process Step #2, or dissipate static on material exiting Step #2.

And, of course, dissipate static on the finished material to keep EFinish low.

When static is well controlled, write down the static readings again along the material flow in Figure 3 from the beginning incoming materials, exiting each process step, and finishing with a reading on the finished material. This ensures that all readings are low and that the static problem is solved.

Solve static problems by using your handheld static meter to locate the sources of static charging. Dissipate static at the sources of charging. And, dissipate static at the process location that has the problem. Then, use your static meter to verify that the problem is solved.

About the Author

Kelly Robinson, PE, PhD can be reached at Kelly.Robinson@ElectrostaticAnswers.com.