Static Measurements Guide Problem Solving

- Published: May 16, 2022

By Dr. Kelly Robinson, Founder, Electrostatic Answers

How do we solve static problems? What is the root cause of the problem?

Finding a static problem is easy. Operations run smoothly and efficiently when there is no problem. We have a problem when static damages the product (quality defect), causes a material jam (down-time), shocks an operator (injury) or ignites a fire (very bad!).

Finding an effective solution for a static problem is hard. The sage advice is to attack the root cause. I’ve heard this advice many times in problem-solving lectures and seminars. Finding the root cause is the hard part. How can we find the root cause of a static problem?

The material flow in many production operations is long, complex and typically crosses organizational boundaries. When the material is polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET) or another electrically insulating material, static charges on the material persist through many operations and through transportation between operations. Because static charges persist for so long (sometimes weeks or months) on insulating materials, the root cause may be far upstream of the problem, perhaps even in another country.

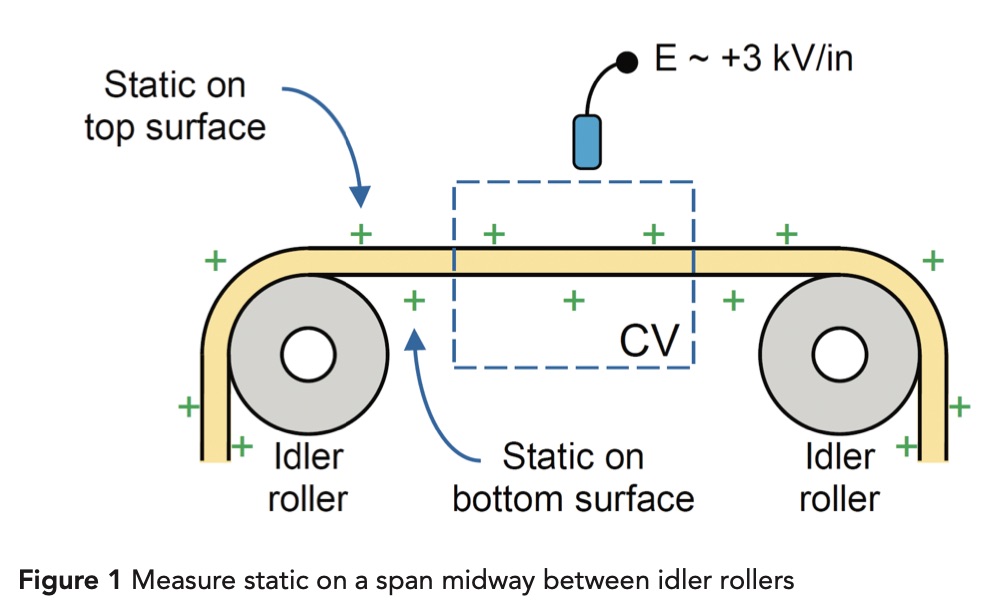

Find the root cause of a static problem by completing a static survey, which is a series of static measurements along the material flow in your operation. Use the handheld electrostatic fieldmeter (ESFM) in Figure 1 to read static on a web span midway between two idler rollers. The electrostatic fieldmeter responds to all of the static charges inside control volume CV. Since there are 3 positive charges inside CV, the reading will be +3 kV/in.

An electrostatic fieldmeter (ESFM) measures the average static over a relatively large area of the web that is typically a 4-inch diameter circle (or larger, depending on the measurement location) on the web. To make reliable, repeatable measurements, follow the three “GeeZE Rules” (see Static Beat | ‘GeeZE’ Rules for Static Readings).*

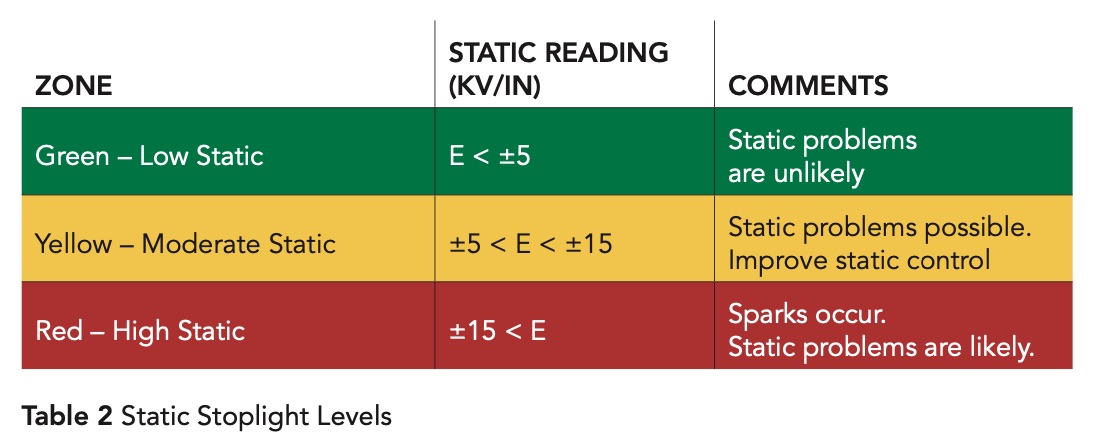

Most static meter display the voltage in kilovolts (kV). Convert the voltage into the nominal electric field by dividing the displayed voltage by the distance from the sensor to the web (see Static Beat | Assess Static Risks Using Electric Fields). Use the static stoplight levels in Table 2 to evaluate your readings.

Static problems are unlikely when readings are low. Good static control systems keep measured levels in the Green – Low Static zone. As you move along the material flow, when you see a reading jump into the Red – High Static zone, you have found a root cause, which is a significant source of static charging. Install a static dissipater to bring the reading down into the Green – Low Static zone.

If static is high on incoming materials, the root cause of the problem is upstream of your operation. While we will certainly do our best to deal with this delivered static, talk with your supplier about attacking the problem at the root cause in their operation. Ask your supplier to track the static performance of their operation by auditing static on their finished goods before shipping them to you. This will ensure that problem-free materials are delivered to you.

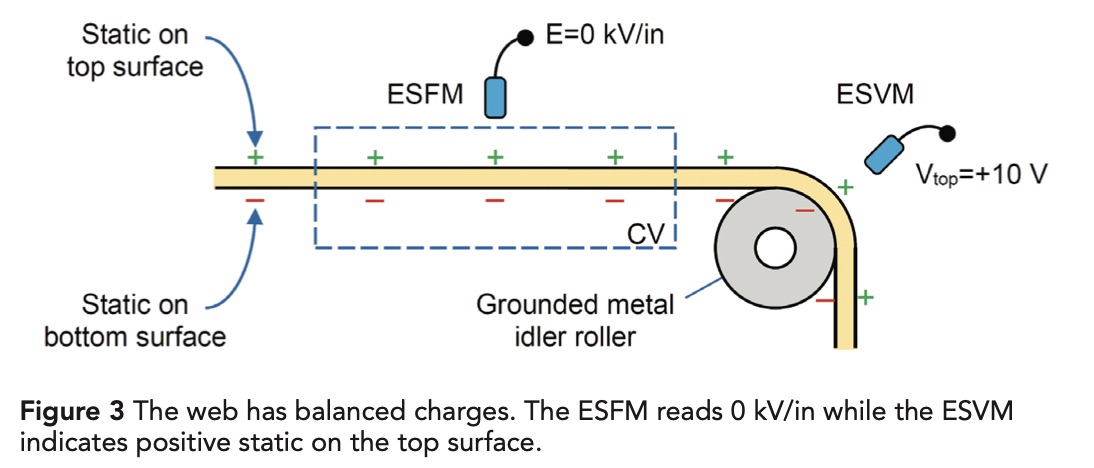

Unfortunately, our electrostatic fieldmeter readings cannot find the root cause of all static problems. High static on winding and on unwinding rolls may be caused by balanced charges on the web in Figure 3 where there are positive static charges on one surface of the web and there are an equal number of negative charges on the other surface of the web. The electrostatic fieldmeter (ESFM) responds to all of the charges inside control volume CV, so it reads 0 kV/in. The electrostatic voltmeter (ESVM) responds only to the charges on the exposed surface, so it indicates positive charges on the top surface.

Use an ESVM to measure the static on one surface of the web at the beginning of the material flow in your operation. Then, measure static again on the same surface near the end of your material flow. With good static control, the voltage on the surface should increase no more than ±0.5 V/mm (±10 V / 0.001 inch) of web thickness.

Perform a static survey to find the root cause of a static problem. Once we find the source of static charging, we know where to install a static dissipater to solve the problem.

For more information, contact: Kelly.Robinson@ElectrostaticAnswers.com.

*https://www.pffc-online.com/static-beat/14478-static-beat-geeze-rules-for-static-readings