Smart Cards | New Technology for Producing RFID Inlays

- Published: January 03, 2017, By Matthias Schwartze, ruhlamat GmbH

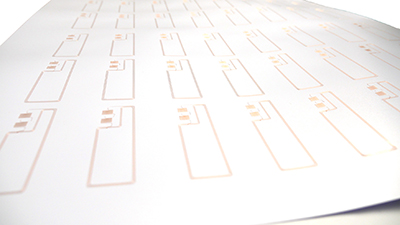

A state-of-the-art wire-embedding machine allows large format antenna production.

Radio frequency identification (RFID) inlays are manufactured throughout the world for many purposes: biometric passports, the contactless smart card market (e-ID, electronic healthcare cards, payment cards, public transportation), and for dual interface applications. At the same time, wire-embedded high frequency (HF) RFID antennas are available and offer a number of advantages over printed, etched, or galvanized variations.

Radio frequency identification (RFID) inlays are manufactured throughout the world for many purposes: biometric passports, the contactless smart card market (e-ID, electronic healthcare cards, payment cards, public transportation), and for dual interface applications. At the same time, wire-embedded high frequency (HF) RFID antennas are available and offer a number of advantages over printed, etched, or galvanized variations.

Among others, the ability to freely select shapes is enticing for card and passport manufacturers, since this can lead to competitive advantages. Further benefits, such as environmental friendliness, durability, and improved product quality, also should be mentioned.

The 3 by 8 standard for antennas per sheet

Until now, the standard format for processing inlay sheets as well as for the production of the inlays for the previously mentioned wire-embedding applications was 3 by 8. For card manufacturers, this means that 24 wire-mounted antennas per sheet normally could be produced.

Depending on the process speed of the wire-embedding machines, modest throughput amounts could be achieved. A means to increase the throughput without adding a second line of production was needed.

RFID inlay production in large format for optimum throughput

By processing sheets in a larger format, the throughput can be increased significantly. For example, using so-called double-sheet sizes (formats up to 730 x 660 mm), a state-of-the-art wire-embedding machine can place 6 by 8 (or 6 by 10) antennas per sheet (see Figure 1).

Through fully automated, high-speed ultrasonic wire embedding, throughputs can be decisively optimized even at a low substrate thickness of 100–400 μm. Both varying substrate material (such as PC and PVC) and wire thickness (80–150 μm) can be processed using up to 12 wire-embedding heads on this machine (see Figure 2). Therefore, throughputs of 4,400 antennas/hour are now a thing of the past.

Maximum freedom through layout-independent substrate suction

Furthermore, card and passport manufacturers worldwide are also capable of improving their production speeds and throughput numbers using a new design feature that allows layout-independent substrate suction. Universal mounting plates enable fast, tool-free set-up for other substrate qualities without affecting precise antenna geometry. Risks, such as deformation or severing of the wire through holes in the mounting plate, are decisively minimized.

Especially with regard to the introduction of new passports, this manufacturing step alone can greatly reduce production times to complete government projects faster.

Radio technology instead of direct contact between module and antenna

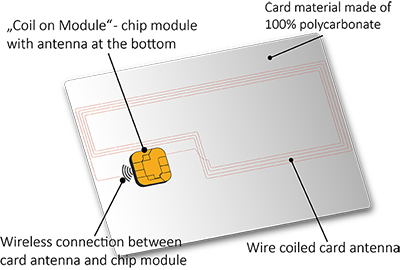

Another innovation in RFID inlay production, known as "coil on module," enables communication between the antenna and chip module without a mechanical connection (see Figure 3).

Using two antennas—one on the module itself and one on the card inlay—communication takes place via electromagnetic waves, which is comparable to the information exchange between the antenna and reading device for contactless cards. This results in new freedom for card manufacturers.

Even more freedom for antenna embedding

Antenna layouts, which previously depended on the position of the chip, now can be produced and placed freely and independently. Production steps, such as cutting the antenna free for producing an electrically conductive connection between the module and antenna—as was previously required for the production of dual interface cards—are no longer necessary. Since the mechanical-electrical connection is no longer needed, the cards are much more durable.

The challenges? Quality and precision!

The most basic prerequisite for the function of this technology is the embedding of the antennas with consistent quality and uniform frequency even when using 12 wire-embedding heads. Particularly when embedding antennas with very small winding distances, high precision is a must. In the future, mechanical engineers from the area of RFID inlay production will have to face this challenge in order to remain competitive on the market.

About the Author

Matthias Schwartze is head of development and product management with ruhlamat GmbH, Marksuhl, Germany, manufacturers of the WCE2000 automatic production system for high-speed wire embedding and RFID inlay production. He has more than 20 years of professional experience in the smart card and passport manufacturing industry. Graduate physicist Schwartze joined ruhlamat in September 2001 as project manager software development. He served as head of product management from 2005 to 2010 and has been part of the management board since 2010.