Roll Handling | Recycled Fiber Cradles Stand Up to Rigors of International Shipping

- Published: December 11, 2012

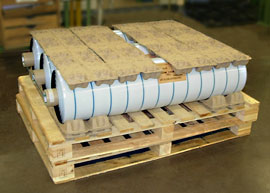

Fiber cradles from Rollguard are 40% less expensive than wooden blocks.

Nitto Denko Corp., a Japanese global manufacturer of films and tapes used in a broad spectrum of industries, was looking for a better way to protect the rolls of product shipped from its manufacturing facilities in Belgium.

Nitto Europe makes specialty films and tapes in Genk, Belgium, for use in the automotive, electronics, paper and printing, building and construction, aerospace and medical industries around the globe. The company was looking for an alternative to the wooden block cradles it was using when it shipped rolls horizontally on pallets.

An ocean away, in Appleton, WI, Rollguard, part of Great Northern Corp.’s Specialty Group, provided the solution.

“First, we went from pyramid packaging to what we call block packaging, because then the load is stackable,” said Danny Timmermans, purchasing and logistics packaging specialist for Nitto Europe. The stackability allowed him to maximize the space in the trucks, rail cars, and ships that carry the rolls to customers in North America, Europe, and Southeast Asia.

“What we were using for our block packaging were wooden blocks with cradle diameters that were customized for our rolls,” Timmermans said. The wooden cradles were put under and between the layers of rolls on pallets.

However, the wooden blocks sometimes caused product damage. “If you put two or three pallets on top of each other, the weight on the blocks could crush the core the film was wrapped around,” Timmermans said. “That would make the roll unusable for the end customer, who could not fit the misshapen core on their machines. So, we were looking for alternatives.”

The search led him to the recycled fiber cradles of Rollguard. “I found Rollguard cradles on the Internet and was intrigued. It’s hard to find cradles of comparable quality in this area, so I had Rollguard send some samples to us,” Timmermans said. “When the cradles arrived, everybody was actually laughing a little bit. We called it egg packaging because the material looked like egg cartons. Everybody was saying, ‘What are they trying to do now?’ because they were so used to the wooden supports. But these fiber cradles hug the rolls better, so the pallets became a lot more stable. The production personnel were won over. We switched to the cradles in February 2010.”

Cradles across the ocean

Nitto Europe is using three different sizes of Rollguard recycled fiber roll cradles in configurations that allow three, four, or five rolls per layer. The rolls typically range in length from 1,000–2,600 cm (394–1,024 in.), in diameter from 160–350 mm (6–14 in.), and in weight from 10–30 kg (22–66 lb).

“Rollguard helped me with advice on the best way to configure the strapping bands so that the rolls are hugged very tightly,” said Timmermans, who has been pleased with the resulting load stability.

Exporting expertise

The nearly 4,000-mile distance between Belgium and Wisconsin has not prevented Rollguard from working out customized solutions and providing support. Rollguard’s experience in exporting and in working with distant customers has proved valuable to Nitto and other international clients.

“Even though they are located far away, we’ve been able to use e-mail and pictures to overcome any challenges we’ve encountered,” said Timmermans.

“We are proud of the international expertise we have developed,” said Rob Swannell, Rollguard general manager. “With our export experience and our growing reputation for reliability and customer service in Europe, we try to make customers like Nitto Europe feel more like they are working with a partner just around the corner.”

According to Timmermans, any initial concerns about the geographic distance and about shipping the molded pulp cradles in 40-ft containers across the Atlantic were quickly put to rest.

“At first, we were concerned about the fact that the cradles would be coming such a long distance and by ship,” Timmermans said. “We wondered how they would look when they arrived. But everything was perfect. The cradles were wrapped with stretch film and arrived in perfect condition. The time from order placement to delivery of the cradles is a consistent six to eight weeks. It is all running very smoothly.”

No impressions make a good impression

The first duty of protective roll cradles is to prevent any damage during shipping and handling. Nitto Europe

also needs protective cradles that will not leave marks or impressions on the outer layers of the film rolls. The pallets, each with three tiers of rolls, are often stacked three high for shipping and warehousing.

“We have to be careful that the bottom rolls do not get imprinted by the cradles from the weight of the rolls above,” Timmermans said. “Otherwise, the first 100 to 200 meters of film will not be usable for the end customers.”

Rollguard’s cradles passed the no-impressions test impressively, and also alleviated any doubts about whether the cradles would retain their structural integrity and performance capabilities in moist environments. “Originally, we were a little bit concerned about how they would perform in Southeast Asia, but there has been no problem,” he said.

Forty percent savings over wood cradles

Even with long-distance shipping, Rollguard’s cradles deliver 40% savings over the wooden blocks, Timmermans said. “Forty percent. That’s significant,” he added.

The savings reflect not only the nestability of the cradles shipped from Rollguard to Belgium and the cost of wood versus molded pulp, but also the cost of treating wood that is being used in export.

“Normally, the wood cradles would have to be heat-treated or fumigated before being exported. So, all the wooden supports, before they arrived here, first got heat-treated and stamped by our pallet supplier, who has a special process for that,” Timmermans said. “The Rollguard cradles have eliminated a lot of hassle and logistics problems.”

Other advantages over wood

Using the fiber cradles instead of wooden blocks has reduced the number of packing material pieces by half. A hinge configuration allows each cradle to be folded back on itself to form back-to-back cradles for upper and lower rolls.

“We are now using a single, hinged cradle instead of two wooden blocks,” Timmermans said. “One piece instead of two is logistically easier.” The lighter weight also reduces freight costs, and the fiber material is easier to work with than wood, he said. “Plus, the wooden cradles were so hard,” Timmermans added. “These are a lot softer, so the rolls cannot get damaged so easily. That’s a big advantage, too.”

Recycled and recyclable

Rollguard’s 100-percent recycled fiber cradles carry one final, but very important, feature of value to Nitto Europe and its customers.

“Using cradles that are made from recycled fiber and are 100-percent recyclable supports our reputation as a clean, green, healthy company,” Timmermans said. “We are working hard to reduce the amount of packaging material we use. We want to become an even greener company, to use recycled packaging and reusable packaging. That’s my job, to work on that.”

This email address is being protected from spambots. You need JavaScript enabled to view it.