Show Preview | Labelexpo Americas 2014 Enhances Focus on Package Printing

- Published: August 05, 2014, By Claudia Hine

Labelexpo Americas 2014 will mark its 25th anniversary when it returns to Chicagoland September 9-11. Show organizer Tarsus Group reports more than 400 exhibitors—including 62 exhibiting for the first time—will occupy 194,000 sq ft of space at the Donald E. Stephens Convention Center in Rosemont, IL.

Labelexpo Americas 2014 will mark its 25th anniversary when it returns to Chicagoland September 9-11. Show organizer Tarsus Group reports more than 400 exhibitors—including 62 exhibiting for the first time—will occupy 194,000 sq ft of space at the Donald E. Stephens Convention Center in Rosemont, IL.

With an enhanced focus on package printing and the brand owner, attendees will discover several new feature areas to explore:

- The Package Printing Workshop will show label printers how to diversify into folding cartons and flexible packaging. The sessions will run for 45 minutes and will take place at 11:30 a.m. and 2:30 p.m. all three days of the show.

- The Inkjet Trail will put some of the available inkjet technologies under the spotlight and compare their results when producing identical label designs on the same label stocks. The press manufacturers are Domino, Durst, EFI, Epson, and Screen USA. Esko will unveil Esko Suite 2014 on the trail. Avery Dennison, FLEXcon, and UPM Raflatac are providing paper, film, and foil substrates for the printed labels.

- Smart Mart where the latest smart and interactive label technology will be displayed. You will see augmented reality, QR codes and scanners, RFID and NFC-enabled smart tags, temperature indicating packaging, and films that prevent food spoilage.

- The Craft Beverage Day conference—for artisan beer, wine, and spirit producers only—will increase their understanding of all aspects of label production, from materials used, the machinery involved, adhesives, and the latest design trends.

- Brand Engagement Through Packaging is a master class on printing technology for brand owners, retailers, label and packaging designers, and buyers. A combination of speaker sessions, guided show tour, and hosted lunch, it will give attendees a robust understanding of label and package printing. The half-day class features industry experts Mike Fairley and Mike Ferrari.

Conference Program

A two-day conference program will be held September 9-10 and includes leading figures from the label and package printing sector. Brand protection, digital printing, next generation materials, and the “Internet of Things” are some of the topics that will be tackled.

PFFC’s On Print columnist Dene Taylor will moderate a session on Inkjet Technologies: printing, substrates and inks for high performance labels. Speakers include Epson’s Michael Pruitt and EFI Jetrion’s Stephen Emery.

For a complete look at the conference sessions, click here.

What To See

Many exhibitors are planning to launch new products at Labelexpo Americas this year. Here are booth descriptions of some of the companies attendees will see. To view the floor plan, click here. Be sure to visit PFFC at Booth 3425.

AccuWeb Introducing its Smallest Web Guide

AccuWeb (Booth 837) will introduce the EVO 150 web guide control, a 24 VDC controller featuring 150 watts of power with the ability to control brushed and brushless actuator motors. At the heart of the new system is a small control module measuring just 6.5 x 4.5 x 1.5 in. with EtherNet/IP communication protocol for convenient uploading and downloading of guide system settings and performance parameters. The control module can be mounted in an EVO enclosure measuring 7 x 5 x 4 in., including one with a flush-mounted, switch-pad HMI panel on the face, or din-mounted in an existing control panel. The EVO 150 is compatible with most existing AccuWeb web guide systems.

AccuWeb (Booth 837) will introduce the EVO 150 web guide control, a 24 VDC controller featuring 150 watts of power with the ability to control brushed and brushless actuator motors. At the heart of the new system is a small control module measuring just 6.5 x 4.5 x 1.5 in. with EtherNet/IP communication protocol for convenient uploading and downloading of guide system settings and performance parameters. The control module can be mounted in an EVO enclosure measuring 7 x 5 x 4 in., including one with a flush-mounted, switch-pad HMI panel on the face, or din-mounted in an existing control panel. The EVO 150 is compatible with most existing AccuWeb web guide systems.

Allen Datagraph Systems Displaying Two Digital Label Systems

Allen Datagraph Systems Inc. (Booth 6115) will demonstrate the iTech CENTRA HS digital label system and the iTech AXXIS HS digital label system. Both are complete turnkey solutiosn that enable label converters to digitally print and finish smaller quantities of consumer-quality labels, in any shape, without costs and delays associated with traditional manufacturing processes.

The LED toner iTech CENTRA HS images consumer-quality labels with brilliant, durable, consistent color at 1200 dpi X 600 dpi, at speeds up to 30 fpm. It delivers high definition printing with four-color stochastic screening. With a maximum width of 12.9 in., the printer has a wide degree of substrate flexibility that does not require top coating. The CENTRA HS prints on most standard pressure-sensitive paper substrates, which are typically half to a third the cost of inkjet substrates. White, metallic, and clear polyester films are also available.

AVT Debuts New Process & Quality Control Solutions

Advanced Vision Technology (AVT) Ltd. (Booth 711) will offer a complete production management workflow system. The solutions being introduced are upgrades that build upon prior technologies. PrintFlow ll is a set of three solutions that have been recently enhanced: PrintFlow Central serves as central storage for AVT’s PrintFlow database that allows users to store, backup, and monitor all aspects of print quality from one access point. PrintFlow Manager ll enables production managers remote access to all AVT PrintFlow databases installed on the company’s 100% inspection platforms. Using its quality statistics features, managers can monitor, analyze and control the quality of the production process from their desktop computers. PrintFlow Online ll is an optimized in-line data editing tool designed to optimize editing time and provide the operator with the most accurate online live quality status and production numbers, via live display or MIS communication.

AVT will debut new process and quality control solutions, including the Helios ll S, which inspects print applications that incorporate holographic foils and other special effects for both brand image and supply chain security. Also premiering are two exclusive new narrow web flexo press control solutions currently being utilized by Nilpeter and Gidue, providing automatic pressure and register control without any human intervention.

Avery Dennison Innovations Drive Growth

Avery Dennison Innovations Drive Growth

Avery Dennison (Booth 119) will showcase more than 15 innovations to the Americas, including Tire Labeling Portfolio, which improves shelf appeal and tracking in challenging tire applications. The materials feature production-friendly gum patterns designed to eliminate oozing and increase conversion speed.

Select Solutions Collection is an offering of 17 application-specific portfolios offering 300 possible Mix & Match constructions, all suited to meet unique labeling needs. This collection includes 427 products with lead times of 4 days or less and low minimum order quantities—from 0.5 to 1.8 million sq in.

CleanFlake Portfolio is an expansion in the company’s range of material designed to advance the recycling of PET containers, which addresses supply imbalances of recycled PET (rPET) and improves cost. CleanFlake now includes Roll-Fed Sleeve constructions that provide excellent clarity, on-bottle coverage, and better yields of PET materials at recyclers.

CleanFlake Portfolio is an expansion in the company’s range of material designed to advance the recycling of PET containers, which addresses supply imbalances of recycled PET (rPET) and improves cost. CleanFlake now includes Roll-Fed Sleeve constructions that provide excellent clarity, on-bottle coverage, and better yields of PET materials at recyclers.

ClearCut S7450 Adhesive is for labels of wine and spirits and non-alcoholic beverages. Wet-out performance allows for effective bonding between the film and the bottle’s surface, even with a high degree of surface imperfections. Pairing S7450 with MDO film allows for enhanced conformability when labeling unique, curved bottle designs. ClearCut technology significantly reduces adhesive ooze and increases productivity.

Beta Industries Offering Show Specials

Beta Industries (Booth 5990) is offering a $500 show discount on the BetaFlex PRO/3D HD Flexo Plate & Image Analyzer. Also featuring Beta Video Rulers for precise, non-contract measurements of large and small distances on films, plates, die, and prints. MicroDynamics MD-3DQC RollScope cell volume measurement in 3D, used for anilox cell volume, gravure, flexo-plate, etched gravure and laser gravure.

Also displaying Betacolor LED-based densitometers and spectros with 1/10 second automatic measuring; Beta Magnifiers hand-held magnfication 10x-100x and visual color separation to contrast all process colors.

Bluestar Silicones To Discuss Latest Developments in Silicone Materials

Bluestar Silicones (Booth 3605) will introduce a flat release profile polymer along with a premium release additive and a crosslinking agent to meet growing demand.

CHILI Publish To Demonstrate Online Document Editor

CHILI Publish (Booth 5202) will present CHILI Publisher, an online document editor made to be integrated in web applications. Once integrated it allows end-users to use the tools available in comparable desktop applications. But since the tools are used in a browser, the user interface can be restricted depending on the needs and skills of the end-user.

Color-Logic Technology on Display at Several Partners' Stands

Color-Logic Inc. will demonstrate its Process Metallic Color System in several of its partner booths at the show (CGS, Domino, Eckart, GTI, HP Indigo, Mark Andy, Screen USA, and Xeikon). With the Color-Logic Design Suite (plug-ins for Adobe) and the Color-Logic FX-Viewer (visualization toolf or the monitor), graphic designers and prepress facilities can do in seconds or minutes tasks that currently require hours if not days.

Colordyne To Unveil New Digital Press

Colordyne Technologies (Booth 6455) will unveil its new 3600 Series press, a full-featured process color digital label and tag production system with an enhanced precision web handling system, powered by Memjet technology.

The CDT 3600 Series provides the latest in proven closed loop tension control technology and is available with low cost inline finishing options and configurations. It also brings several benefits to the Production Class Digital Color Printing System including, but not limited to, enhanced print quality; increased resolution of 1600 x 1375 dpi; drastically reduced RIP times; speeds up to 225 fpm (69 mpm); and a more user-friendly interface. The new CDT 3600 Series web handling system also provides flexibility and modularity for custom configurations and future faster speeds.

Cosmo Films To Display Extensive Label Portfolio

Cosmo Films (Booth 917) will show more than 30 label films for self-adhesive, wrap around, and in-mold labels. Its Universal Print Receptive label stock film's coated surface has excellent adhesion with all kinds of ink. Suitable for all printing techniques, it has stiffness for all dispensing and die-cutting operations.

Other products include metallized film with top coating on metallized as well as unmetallized sides for applications where aesthetics are of prime importance. A white opaque cavitated high matte label film provides paper-like appearance to the self-adhesive labels and is designed as a non-reflective label substrate. Also showing a coated HPI (DP) grade form for excellent printing results on HP Indigo presses.

Davis-Standard Showing Liquid Coating Capabilities

Davis-Standard (Booth 1041) will display the Global Advantage of its Liquid Coating Group. The company will discuss its new curtain slide coater, five-roll silicone coater, and the dsX Flex-Pack extrusion coating line. The curtain slide coater applies a single layer coating at up to 2,800 fpm with expansion capabilities up to two additional layers. The new five-roll silicone coater also offers impressive rates, capable of applying 100% silicone at 2,400 fpm. This coater is constructed of stainless steel for ease of cleanup and includes a state-of-the-art mist removal system.

Also offering coating equipment from the Series 1000 dedicated, Series 2000 component style, and Series 3000 and 4000 cartridge designs. The Series 1000 two-roll primer coaters are utilized with extrusion coating applications.

For cost-sensitive flexible packaging applications, the dsX Flex-Pack extrusion coating line provides better end-product quality, greater uptime and productivity, reduced waste and production costs, and application versatility.

Domino To Demo Digital Press

Domino (Booth 6523) will show roll to roll printing as well as in-line finishing with its N610i digital UV inkjet label press said to reduce costs through lowering material waste and increasing throughput. Delivers highest print quality on a broad range of substrates.

Domino is on the Inkjet Trail at Labelexpo, offering a close look at labels printed on the DOMINO N610i digital color + white UV inkjet press. Will present the press printing on various substrates with a different material each day of the show. Also debuting 7-color CMYKOV + W with presentations each afternoon.

Dover Flexo Electronics To Show New Tension Control Products

Dover Flexo Electronics (Booth 5500) will show new tension measurement, display, and control technology, like the EasyWeb Torque Controller, the Fire-Guard2 Intrinsically-Safe Tension Amplifier, and the new communications features on the SteadyWeb5 Tension Controller.

Dow To Unveil Advanced Silicone Release Coating

Dow Corning (Booth 1340) will unveil the latest addition to its Syl-Off Advantage Series of solventless silicone release technologies designed to promote reliable high-speed/high-volume production in ultra-flat release systems. Syl-Off SL35 Release Modifier, the next generation of controlled release additive technology for low-platinum, solventless systems, also will be featured.

Also highlighted will be Syl-Off SL 181 and Syl-Off SL 581 solventless release coatings that feature stable, flat release profiles and low platinum levels for curing. These technologies help reduce the potential for web breaks after die-cutting and during label dispensing. The facilitate fast line speeds without misting and are suitable for a variety of applications.

Dunmore Announces Roll-to-Roll Conversion Calculator App for Smart Phones

Dunmore Corp. (Booth 1357) offers a free smart phone app that is a convenient roll-to-roll conversion calculator for label converters and users for continuous web substrates. It is available for use on iPhones and Android devices and can be downloaded at the booth, which live demonstrations will held.

The DUNMORE Roll-to-Roll calculator is foremost a roll diameter calculator. It uses film thickness, roll diameter, and core size to determine the total length of the substrate. Conversely, it calculates the overall roll diameter if you use the film thickness, length, and core size as inputs. Also calculates yield from length, total material needed from label parameters, yield using specific gravity, conversations for area, weight, distance, and thickness, and allows users to determine the resistance of a metallized substrate.

DuPont Packaging Graphics Features Flexo Plate and Equipment Technologies

DuPont Packaging Graphics (Booth 5403) is highlighting new flexographic plate and equipment technologies, including the DuPont Cyrel FAST DFUV plate, the DuPont Cyrel FAST 1001 TD processor, and the DuPont Cyrel FAST DFR plate, all designed to deliver quality, productivity, and sustainability benefits to tag and label printers.

The new FAST DFUV plate is a thermal process plate that comes up to color quickly, minimizing startup waste, and prints smooth and dense solids, without compromising dot gain, highlights, and resolutions.

The new FAST 1001 TD is a small format thermal platemaking system that has been redesigned and streamlined for improved dimensional stability and efficiency. It uses a unique thermal management system and multiple roller design to improve clean-out, provide more consistent relief depth and a more uniform floor especially with thin gauge (0.045 in.) plates often used for tag and label applications.

Durst To Participate in Inkjet Trail

Durst (Booth 5901) will exhibit the Tau 330 UV Inkjet digital label press, featuring live demos as part of the Inkjet Trail. Also showing low-migration, low-odor inks, developed specifically for the industrial label, primary food packaging, and pharmaceutical segments.

Dyna-Tech Introducing Biodegradable Adhesive

Dyna-Tech (Booth 1660) is introducing DyTac 9577, a biodegradable and compostable pressure-sensitive adhesive. It is a rubber-resin emulsion, formulated as a permanent adhesive based on components reported to meet the requirements of DIN CERTCO and BPI for biodegradability and compostability. The adhesive's primary components are all naturally occurring materials and are 98% bio-based content, based on Radiocarbon Analysis (as defined by Iowa State Univ.).

The resin components of the adhesive meet ASTM D6400/6868 for compostability, and all other components are certified to be biodegradable by the suppliers. DyTac 9577 has a minimum application temperature of +20 deg F, a service temperature range of -20 deg F to 250 deg F, and meets federal regulations for indirect food contact 21CFR175.105.

Epson Showcasing Full Range of Label Solutions and Finishing Unit

Epson America (Booth 5813) is showcasing its full range of prime, sub-prime, and GHS label solutions plus a laser finishing unit. It will show, for the first time in the US, the SurePress L-6034VW and L-6034V single-pass industrial press using PrecisionCore technology in a linehead configuration and the first to offer Epson's new LED-cured UV ink with in-line digital varnish technology.

As part of the Labelexpo Inkjet Trail, Epson will be printing on the SurePress L-4033A/AW inkjet digital label press, and attendees will be able to collect samples and compare results with four other press manufacturers' samples. Upgrades to the SurePress L-4033A/AW include a clear sensor that will allow for printing on a clear substrate with a clear liner, as well as improved Variable Data Printing processing for maximum label customization.

Esko Offers Updated Preproduction Toolset

Esko (Booth 5202) will display its complete preproduction solutions from file to plate for label production. A major emphasis at the booth will be Suite 14 software tools, which support and manage the packaging and print processes at brand owners, retailers, designers, packaging manufacturers, and print service providers.

Also showing Equinox Expanded Color Gamut (ECG) Technology for converting packaging graphics from CMYK and spot color to seven-color process as well as examples of Full HD Flexo for Labels, which features adapted screening and standard operating procedures for the label and tag industry.

An Esko CDI Spark 4835 flexo plate imager with inline UV and Full HD Flexo will be exhibited at the booth.

FFEI To Reveal New Graphium Features

FFEI Ltd. (at Fujifilm Booth 5621) will demonstrate the new over white capability of its hybrid digital UV inkjet press, Graphium. Adding an over white print capability not only increases the overall flexibility of what can be produced but also dramatically increases the potential opacity when used with the Graphium under white. This new, unique capability provides converters with a host of additional ways to enhance the overall look and feel of their labels.

The use of over white can significantly enhance text. For example when a colored background with white knockout text is required, it often suffers a lack of clarity. In these cases, small text in an opaque white may be overprinted or a combination of a knockout with overprinted white used to clean-up and provide clarity. Additionally over white provides enhanced definition and clarity and brings the highest levels of flatness in pure white areas of a label. This is achieved by printing a second white as a mask of the visual effect of the under white.

FFEI also is announcing a number of enhancements including the capability to support substrates of 40-600um allowing the thinnest liners to heavy duty vinyl to be used. Furthermore, Graphium is capable of printing to an ISO 12647-2:2204 standard.

Flexo Concepts to Feature Doctor Blades, Wash-Up Systems

Flexo Concepts (Booth 5730) will show its TruPoint Orange doctor blade, with superior blade life, safety characteristics, and quality metering ability. Several OEMs, including Grafisk Maskinfabrik (Booth 6125) will feature the TruPoint Orange blades on their equipment at the show.

Also offering the TruPoint QuikWash System and wash-up blades and MicroClean dry media anilox cleaning systems. Products are designed to improve print quality and reduce operational costs for flexo and offset printers.

Flexographic Technical Assn. Touts Member Benefits

Flexographic Technical Assn. (FTA) (Booth 545) will showcase its diverse portfolio of membership benefits. On display will be the newest educational publications, including FIRST (Flexographic Image Reproduction Specifications & Tolerances), Flexography: Principles & Practices 6.0, and the FLEXOGRAPHY 101 Booklet series. Experts will be on hand to discuss the association's online certification and training initiatives, including FIRST Press, Prepress, Implementation Specialist and Company Certification programs.

Flint Group To Show Plates, Inks, and Sleeves

Flint Group (Booth 840) will feature comprehensive solutions for narrow web label and package printing needs. Two divisions will jointly display at the booth.

Flint Group Flexographic Products division will show nyloflex ACE UP Digital and ACE Digital printing plants with long run life and excellent stability for water, solvent, or UV flexo inks. Also showing its rotec High Speed Sleeve that reduces bounce-induced skipping and the rotec Label Sleeve with increased dimensional stability and excellent edge stability. The FlexoToolbox App is an interactive collection of tools to assist printers with flexo prepress operations.

Flint Group Narrow Web division will introduce EkoCure products to include metallic inks, UV shrink whites, UV rotary screen colors, EkoCure IVORY and EBONY, and a range of coatings and adhesives. EkoCure ANCORA UV flexo low migration inks for package printing will be shown. CombiWhite X2 is a new range of rotary screen opaque white inks will be displayed as well as water-based film inks and new low migration technologies, suitable for flexible packaging.

GFI Innovations To Debut Ink Dispensing System

GFI Innovations (Booth 547) will introduce the AccuBlend-LV Ink Dispensing System for low viscous flexo inks. The user-friendly system offers a host of benefits to improve control over the process, schedules, and workflow of ink dispensing. Self-contained machine combines attractive design and compact footprint. with a two-stage dispense valve design, unit features a dozen integrated 5-gallon vessels.

New COLORBOOK dispenser software with touch screen controls drives this machine. Nearly all dispenser and data management functions are contained on one screen, and navigation, the tracking of lot numbers, and batch color correction are functions made easier to maintain, especially when using work-off inks.

Glunz & Jensen Introduces Eco-Friendly UV LED Lamp Technology

Glunz & Jensen (Booth 5435) is introducing UV LED lamp technology with 60% energy power savings along with complete removal of mercury disposal, ozone and heat emission. The lamp offers instant on/off technology, removing the need for warm-up time. The lamp also offers an extreme accurate and flexible wave-length operation.

GMG To Show Color Management Workflow and Proofing Technologies

GMG (Booth 6511) will highlight GMG OpenColor, a proofing technology that precisely predicts the color appearance of printed inks, particularly spot colors and overprints--inks printed on top of each other. This allows the ability to assure a proof will accurately simulate a printed result. Also showing GMG ColorMaster 2.1, which is designed for companies that want to keep their data in the RGB color space as long as possible. It also helps converters who process print globally and need to consider different standards.

Will demonstrate GMG ColorProof 5.5 proofing software, GMG ColorServer 4.9 color management software, and GMG CoZone, a modular production environment based in the cloud.

Goss Offers New Web Offset Solutions for Labels & Packaging

Goss International (Booth 1824) will illustrate how flexible configurations featuring Sunday Vpak press technology can deliver a compelling proposition for high quality label and flexible packaging applications. The web offset solution is said to turn marginal short-run jobs into sustainable, profitable ones, with the advantage of plate and imaging costs that are a fraction of those associated with flexo and gravure. Web offset also ensures far greater flexibility and control, and allows converters to offer their customers later artwork deadlines.

Other advantages include premium print quality, greater color control, and the standardized, repeatable web offset process, as well as the ability to handle a wide variety of substrates, including films as low as nine microns, at high speeds.

GSE Dispensing To Offer Ink Logistics Solutions

GSE Dispensing (Booth 558) will present its Colorsat Switch, a dispenser automating the supply of process colors to the press. Discover how integrated ink logistics solutions for flexo and gravure users result in efficiency improvements, reducing setup times and material waste and improving business processes, especially stock control.

Harper Corp. of America Will Offer Demos

Harper Corp. of America (Booth 401) will demonstrate its patented award-winning QD ink proofing system, HEX plate sleeves and bridge sleeves designed to decrease downtime and minimize makeready, and the HIVE (High Image Volume Engravings) product line, including LaserKote XDI and XLT anilox rolls. Representatives will be on hand to showcase these products and services and provide additional information and insight regarding this technology.

IIJ Launches Fully Automated Ink System

IIJ Industrial Inkjet Ltd. (Booth 3710) will showcase its MK2 ink controller system publicly for the first time. The MK2 controller is said to have numerous improvements over the former system from IIJ, which is also the sales and technical support center for Konica Minolta inkjet division outside of Asia. The controller has been in development for two years driven by demand for larger inkjet systems.

IIJ Industrial Inkjet Ltd. (Booth 3710) will showcase its MK2 ink controller system publicly for the first time. The MK2 controller is said to have numerous improvements over the former system from IIJ, which is also the sales and technical support center for Konica Minolta inkjet division outside of Asia. The controller has been in development for two years driven by demand for larger inkjet systems.

Benefits said to include virtually no ink wastage—individual purge by color; compatible with a wide range of UV, solvent, and water-based and food grade inks; easily expandable into more colors and more heads per color; and tank design allows for a high level of acceleration, meaning suitability for both scanning and single-pass applications. Design is suitable for low-migration inks, white inks, varnishes, primers, metallics, ceramic, conductive, and security inks. This opens up new applications such as packaging, glass, flooring, or direct-product-decoration.

INX Intl. Has New Label Technologies

INX Intl. Ink Co. (Booth 6411) will show the new Komori NW210 inkjet UV digital narrow web press with in-line laser cutting. Powered by JetINX, it’s the latest addition to the EVOLVE Advanced Digital Solutions line and provides label converters and packaging printers an opportunity to transition into digital printing with short-run production. Capable of delivering UV-LED cure single pass output up to 80 fpm on any label stock, it combines printing and conversion to provide brilliant color and easy production of printed labels at a maximum printing width of 210 mm.

A new HMJ-200 small batch ink dispenser from HMJtech Dispensing Solutions will be demonstrated in the INX booth. Designed for the tag and label market, it offers significant benefits for small to medium-sized batches. It is available for water-based or UV-curable ink and is configurable up to14 base ingredients from kits, drums, totes, or bulk.

Visitors will have three water-based flexographic ink formulations to choose from. The AquaTech ION-T Thermal series is used for a wide range of thermal laser printers and the ION-P Paper series prints on most prime label, semi-gloss, and EDP substrates, plus an array of pressure-sensitive and tag liners. The ION Film Glow & Sheen Metallic series prints on most prime label, semi-gloss, and EDP substrates, as well as most treated films and foils.

iSys Label Will Demo BS5609-Compliant Label Printer

iSys Label (Booth 6413) is offering live demonstrations of the EDGE 850 and APEX 1290 digital label printers. The EDGE 850 is a roll-to-roll digital label printer for printing full color BS5609-compliant chemical drum labels on demand. It allows users to eliminate the need for ordering pre-printed labels, reduce inventory and wait times, and allows users to customize each label with variable information in full color - all in a single pass. Users will be capable of printing 2000 labels in less than 20 minutes.

The APEX 1290 is a digital label press for short to mid run production. With media print widths ranging from 3 in. to 12.9 in. wide, users can print 28,000 production-worthy labels in less than 37 minutes.

Jindal Films Displays New White, Lightweight Film

Jindal Films (Booth 829) will display its new white, lighteight Laabel-Lyte 52LLC247 oriented polyolefin (PO) film, which extends its family of conformable films, including clear Label-Lyte 52LLC210, that offer excellent converting characteristics, conformability, and flexibility for pressure-sensitive label applications.

Jindal Films (Booth 829) will display its new white, lighteight Laabel-Lyte 52LLC247 oriented polyolefin (PO) film, which extends its family of conformable films, including clear Label-Lyte 52LLC210, that offer excellent converting characteristics, conformability, and flexibility for pressure-sensitive label applications.

The conformability and squeezability of Label-Lyte 52LLC247 allow the label to remain intact and appear new even after multiple squeezes of the container. The printable surface enables point-of-sale impact to be enhanced for a wide range of products including health and beauty care, household products, beverages, canistered, or bottled food. Also said to allow high quality tailored designs that reduce wrinkling and darting of the labels, even after the container is repeatedly squeezed. The film is compatible with multiple print technologies including metalized inks, hot stamp and cold foil decoration, and displays excellent white gloss for an enhanced look.

JV Imaging Solutions Introducing Platemaking Solution

JV Imaging Solutions (Booth 5523) will offer live demonstrations of its EVO 2A platemaker, a compact all-in-one unit with pre-wash section for digital plates. It features one pass in-line pre-wash/wash/cleaning/wiping.

Also showing LUX In-the-Plate technology from MacDermid that provides all the benefits of LUX Lamination but with the convenience of flat top dots right out of the box. No additional platemaking steps or equipment are needed. LUX ITP 60 is a 60 durometer plate that offers 1:1 mask-to-plate imaging capability, thus eliminating the need for a bump curve. By removing the bump curve, printers are able to expand the available color gamut and print a smaller dot.

Kodak Displaying Flexo Plate System

Kodak (Booth 5606) will highlight the FLEXCEL NX system that provides a step change in flexo print performance with fewer plates, fewer spot color inks, and less press downtime. PRINERGY Workflow automation tool for packaging will be demonstrated. Said to deliver outstanding performance and reliability and best-in-class productivity.

Label Traxx To Showcase Version 7.1

Label Traxx (Booth 6023) will unveil Version 7.1 of its MIS software system, which uses the latest 4D database technology. It focuses on advancing the "paperless office," with a new external document system that can store multiple document types, including PDF, .MOV, .DOC, .XLS, and others. The storage system has been added to all areas of the program for storing the paper trail, proofs, ISO, and other information. Also new to Version 7.1 is on-screen backup verification, where users can view from the Home screen the last successful backup. If a backup is not complete, an e-mail notification is sent, thus assuring users that data is backed up in case of emergencies.

Additional enhancements found in Version 7.1 include an improved connection from JDF/JML to the Esko Automation Engine and digital press front ends with more specific job data being sent. Here, messages are automated when job changes are entered. Version 7.1 also features the integration of Gantt Chart Software, a user-friendly, visual system for scheduling jobs and projects.

Mark Andy To Demonstrate Total Solutions Partnership

Mark Andy (Booth 319) will debut the new Mark Andy Digital Series hybrid inkjet printing platform that runs high quality jobs at speeds of 250 fpm/76 mpm. The hybrid platform is designed to be highly configurable and features high-resolution six-color UV inkjet printing (CMYKOV+W) with top coating and fully integrated in-line modules including flexo printing, converting, and decorating options. Features Quick Change Die Cut (QCDC) technology. Demonstrations will be held daily at 9:15, 10:15, 11:15, 1:15, 2:15, and 3:15.

Also showing the Full HD Flexo certified Performance Series press, and Rotoflex VS1330 and Rotoflex VL1440, now both fully servo.

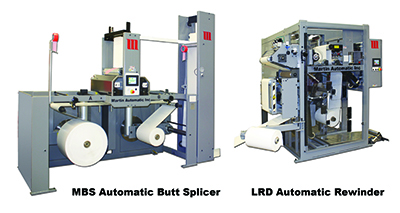

Martin Automatic Demos Splicer and Rewinder

Martin Automatic (Booth 811) will showcase its automatic roll change technology, including running demonstrations of the full-featured MBS splicer and LRD rewinder. Label printers and converters will have hands-on opportunities to see how non-stop splicing and rewinding helps them get the job done faster, with less waste and with higher profits.

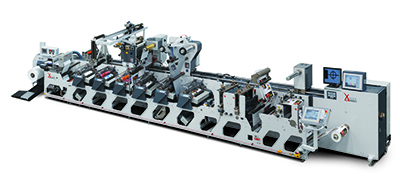

MPS Introducing UV Flexo Press with Plate Rolls or Print Sleeves

MPS (Booth 1321) is introducing its flagship EF flexo press to North American printers. It features a choice of either plate rolls or print sleeves. High quality production press features both UV and hot-air drying technology, allowing users to print diverse substrates including film, paper, shrink sleeves, and flexible packaging.

Three automation features of the EF help maximize the performance of the operator: job memory, AutoTech technology, and iStop technology. With the use of the servo drives, all press settings are automated in the EF, which reduces set-up waste and offers simpler machine operation. AutoTech enables operators to determine the desired web path and the machine automatically teaches itself the web path being used. The iStop technology optimizes stops and starts during printing, allowing the operator to stop the machine at any point during the production run with no additional waste occurring when the press is restarted.

Muller Martini To Demo VSOP Web Press

Muller Martini (Booth 1344) is showcasing its VSOP (variable sleeve offset printing) web press technology with a pneumatically powered VSOP print tower that’s been modified with a see-through doorway. The demonstration shows just how easy and fast it is to change the sleeves and start a new job.

Muller Martini’s mid- and narrow-web offset presses—the VSOP, Alprinta, and Concepta—offer impressive versatility in offset, flexo, gravure, digital, and screen printing, as well as various processing and finishing modules. With both the VSOP and Alprinta-V, size changes are made by exchanging lightweight sleeves and carbon-fiber cylinders instead of entire printing inserts.

Multi-Plastics To Celebrate 35th Anniversary

Multi-Plastics (Booth 1312) will celebrate its 35th year in business at Labelexpo. The company has grown through diversification and expansion and now has four divisions including film and sheet extrusion and film distribution from ten locations in the US, Canada, and the UK.

The company slits and converts thin gauge plastic film in rolls or sheets to supply the envelope, carton, label, printing, and packaging industries.

OKI Will Demonstrate Printing and Finishing Solution for Short Runs

OKI Data Americas (Booth 1245) will show the new C711DW and HS711DLF digital color label printer and finishing system for short-run commercial applications. Together the devices create full color finished labels on-demand and with ease, incorporating digital die-cutting and film lamination. The C711DW utilizes OKI LED printing technology, including OKI label management software from HYBRID Software as a front-end solution. It prints up to 25 fpm in continuous feed mode and handles a variety of media, including paper, polyester, vinyl, and adhesive-backed substrates at widths of 6.5 to 8.5 in. and a maximum outside roll diameter of 14 in. on a 3-in. core.

Also being demonstrated at the booth is the OKI pro511DW digital web press that offices enhanced features and functionality including a Proactive server, Harlequin raster image processor, and HYBRID front-end software, plus a heavy duty rewinder with a pre-assembled slitter. It has the capacity to produce thousands of production-quality full color labels per day.

The OKI pro900DP envelope press has HD color printing capabilities and features embedded an EFI Fiery System 8e controller with SmartRIP technology for fast, automated color workflow and job management, plus color consistency and accuracy.

OMET Will Debut 17-in. XFlex X4

OMET (Booth 3123) will show the XFlex X4 in a 17-in. (440-mm) width. XFlex X4 is the entry-level press offering top-rate electronic equipment including the Vision register control system, twin servo-motors on each printing unit, and label and film printing capabilities. The addition of the extended width to the XFlex X4 project has been thought just for the American market, where printers have the objective to accommodate with ease both the printing of short and medium runs of labels to long runs of flexible packaging.

Also showing an XFlex X6 530 in ten colors, which offers modularity, flexibility, and multi-process capabilities. XFlex X4 will demonstrate the rapidity of changeover and the excellence in self-adhesive label printing for the wine and spirits sector. On the XFlex X6, shrink sleeve printing will alternate with self-adhesive converting to show the potential of the machine in terms of versatility and highly consistent results. Both machines deliver outstanding performance on many products to include film printing, self-adhesive, special papers, shrinkable materials, in-mold labels, aluminum, and special applications.

Plastics Suppliers To Show Film for Shrink Labels

Plastic Suppliers Inc. (PSI) (Booth 3634) will have samples of Polyflex, its recently released transverse direction orientated (TDO) heat-stable oriented polystyrene shrink (OPS) label film for shrink label converters. It offers improvements in cost and quality as well as less than 0.4% shrinkage at 95 deg F for 24 hr.

The new heat-stable OPS label film also offers virtually the same shrink curves and machine direction (MD) growth as PETG-based shrink film, making it an even more attractive alternative, since existing OPS already adds a more than 25% increase in yield over PETG.

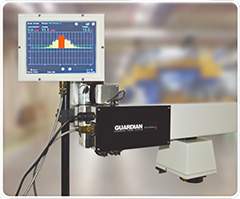

Process Sensors Introducing New Profiling System

Process Sensors Corp. (Booth 1828) will feature the new Guardian OI based cross direction profiling system, which features a single frame with 12-in. touch screen profile display.

Process Sensors Corp. (Booth 1828) will feature the new Guardian OI based cross direction profiling system, which features a single frame with 12-in. touch screen profile display.

The Guardian System can measure moisture, wet end water-based coat weight, film thickness, and organic deposition on a wide variety of substrates, including paper, film, foil, metal, nonwovens, and more.

Schober To Highlight Rotary Die-Cutting Technology

Schober (Booth 1317) will feature rotary die-cutting designed for converting of digital or conventionally printed film and foil, laminates, coated paper laminates, and composite materials. The Spider high-speed programmable robotic stacking and counting system combines acceleration, velocity, and precision at speeds of up to 50 m/min (164 fpm)—allowing stacking of various types of products within the same print image. Called ideal for today’s digitally printed in-mold labels; this technology allows nested product configurations with a combination of large/long and small products. The RSM-Digi/VS is ideal for use with OPP, PE, PS, PET, and more.

This new technology is available with web widths to 850 mm (33 in.) and die-cutting repeat of 1.220 mm (48 in.). A 100% product inspection system with defective product discharge is available. In addition to the robotic Spider delivery, other proven stacking/delivery devices available include “M” stack for short runs, “S” stack for longer runs, “SM” for awkward products, and “SMA” a fully automated solution.

Screen USA Will Showcase Digital Printing and Flexo Plate Imaging Solutions

Screen USA (Booth 3005) will feature the Truepress Jet L350UV press for cost-effective production of high quality, short to medium run labels and packaging. Affords printers who operate flexo, screen, or gravure equipment a reliable entry into variable-data digital label printing. Prints precise color graphics and well-defined text at a top speed of 164 fpm on roll media from 3.9 in. to 13.7 in. wide. Handles text as small as 4 points, providing excellent legibility for large amounts of information found on drug and supplement labels, as well as many other types of product labels. Press will be demonstrated with a finishing line from AB Graphic Intl.

Also showing the PlateRite FX87011 digital imaging recorder outputs narrow-web flexo digital paltes, letterpress digital plates and thermal ablative film. An option for imaging thermal offset plates is available.

SPGPrints Demos UV-Inkjet Press & HD-Digital Imaging

SPGPrints (Booth 530) showcases its modular DSI digital UV inkjet printer for short-run, variable data, and personalized labels. Offering production speeds of up to 700 sq m/hr and available in widths from 135–530 mm, the system is a competitive alternative to flexo for production runs of up to 5,000 linear meters and beyond. The printing platform, with CMYK as standard, can be built or latterly extended with up to six more print heads. Options are orange and violet to make 90% of the color gamut achievable, digital white with “screen-look” opacity, and digital primer to maximize substrate compatibility, while minimizing waste.

Also showing the variLEX hybrid CTP (computer-to-plate) and CTS (computer-to-screen) imager provides a single, digital imaging solution for high-definition flexo, dry-offset, screen, and letterpress printing. Maximum resolution is 4,000 dpi. The variLEX can be equipped with a multibeam diode laser system for ablating the black mask and/or a multibeam diode laser system to directly expose UV-sensitive materials like screens. Its integrated inline exposure system facilitates ablation and exposure in one step. This eliminates the need for offline exposure and ensures sharp printing results.

Also showing the variLEX hybrid CTP (computer-to-plate) and CTS (computer-to-screen) imager provides a single, digital imaging solution for high-definition flexo, dry-offset, screen, and letterpress printing. Maximum resolution is 4,000 dpi. The variLEX can be equipped with a multibeam diode laser system for ablating the black mask and/or a multibeam diode laser system to directly expose UV-sensitive materials like screens. Its integrated inline exposure system facilitates ablation and exposure in one step. This eliminates the need for offline exposure and ensures sharp printing results.

Sun Chemical To Take Customers from Concept to Consumer

Sun Chemical (Booth 5413) will showcase its full range of solutions for the narrow web, tag and label, and converting markets, from inks, coatings, and consumables to brand protection, low migration, pre-press services with high-definition digital plate technology, packaging design/brand consultancy, and a dispenser program which lowers ink spend by up to 25%.

Visitors will be introduced to Solaris System, a line of inks and consumables and that includes products for virtually all narrow web applications, from self-adhesive and in-mold labels to wrap arounds, shrink sleeves, tubes, and food and pharmaceutical packaging. Also on display will be SunSpectro family of reverse/surface print inks. A range of coatings will be on shown, including SunInspire sensory coatings and SunLase laser marking solutions.

Visitors will be introduced to SunGraphics high definition flexographic plate technology, with Esko HD software and CDI high resolution imaging. Converters that utilize the HD printing plates can print with an image quality of up to 4,000 PPI.

T+Sun, a partnership between Sun Chemical and T+Ink, will be offering new packaging technologies at the Smart Mart Booth 2015. Smart Mart is a new feature at the show that displays label technology of the future. T+Sun also will be present at Sun Chemical's booth and will demonstrate Touchcode, an imbedded code that when touched to a smart device, activates a range of options, including security and web interaction.

Telstar To Show its Gallery of Retrofit Equipment

Telstar Engineering (Booth 1818) will show the servo-driven DecoMod set-up, a versatile retrofit that expands printing and converting capabilities of any press, including Cold Foil and Cast & Cure. Also showing a self-contained UV rotary screen unit and Interchange Screen Unit that switches to a UV Flexo Unit in minutes. A Servo Die with Hot Stamp System can be added to nearly any press within the print zone with no press colors sacrificed. Also showing unwind and rewind solutions and standalone servo nip assembly with closed-loop tension control.

tesa tape Will Display Plate Mounting Tapes

tesa tape (Booth 5701) will display high-performance plate mounting tapes for the ultimate in graphic reproduction in flexo printing applications. Also offer ease of use in mounting and demounting. Company will show its new Foam Advisor tool, which is designed to help users find out which tape hardness best suits their application.

TRESU Presents Ancillary Products to Improve Ink Flow

TRESU Group (Booth 1308) will highlight its F10 iCon ink supply system that automates ink pressure, viscosity, and temperature control in flexo presses. This ensures a constant, accurate ink density on the printed substrate and prevents air from contaminating the ink chamber.

TRESU Group (Booth 1308) will highlight its F10 iCon ink supply system that automates ink pressure, viscosity, and temperature control in flexo presses. This ensures a constant, accurate ink density on the printed substrate and prevents air from contaminating the ink chamber.

Chambered doctor blade systems include the FlexiPrint IMW E-Line, for web widths up to 1,800 mm (70.8 in.) and speeds up to 500 mpm (1,640 fpm); and the closed-cassette FlexiPrint reservoir, which needs no pump and operates at press speeds of up to 300 mpm (984 fpm). The E-Line system, including clamp, allows for safe blade changeover in less than two minutes. A patented Rubber Seal System ensures an airtight closure, eliminating the chance of leakage and allowing long-term storage of ink, for instance when production is interrupted during weekend shutdowns.

Wikoff Color Corp. To Show Inks and Coatings

Wikoff Color Corp. (Booth 1011) will display its newest UV flexo system, inkjet inks and coatings, and specialty coatings—Raised Image, Liquid Foil, Reticulation, Strike through, and Soft touch.

Wink To Launch GapControl

Wink US (Booth 5920) will launch the adjustable anvil cylinder GapControl, which permits a highly precise, double-sided adaption of the gap (and thus the liner strike) to various applications and materials. Its high stability makes cutting-through possible without any problems at high production speeds.

Also showing the ultra-hard MCR coating for flexible dies that increases the tools’ durability, especially when die-cutting very abrasive (thermal) materials in long runs. Special versions and finishings of the SuperCut flexible dies will be displayed, including ProShift technology for staggered die-cutting, an ideal solution for blank labels.

For a complete list of exhibitors, click here.