NEW InsigniaX3 machine cutting 30mil thick laminated materials

Rollem's NEWEST InsigniaX3 model of machine produced specifically to die cut through 0.030" / 0.76mm thick materials. Shown running a 13x19" sheet of 10pt laminate on both top and bottom of a 10pt teslin material. Cut anything from 0.004" - 0.030" on the Insignia system. For more information please visit www.insigniadiecutting.com or call (800) 272-4381 to speak with a Rollem sales representative.

Precision Punch Machine 211035

This application required punching a roll of material approximately 4" wide and then rewinding it back onto a core. Precise holes were placed in the material. The cycle rate requirement was approximately 400 punches/minute with a tolerance of +/-.008". #AZCO

For more information about this product, go to http://www.azcocorp.com/custom-high...

To see more punch machines, visit the link below:

http://www.azcocorp.com/components/...

More custom and precision machines in action can be watched below:

https://www.youtube.com/watch?v=ZEJ...

https://www.youtube.com/watch?v=X96...

Follow us on your favorite social platform!

Facebook: https://www.facebook.com/AZCO-Corpo...

LinkedIn: http://www.linkedin.com/company/azc...

Google+ : https://plus.google.com/11006207813...

Rollem Insignia6 inline w/ Chameleon folder/gluer

Shown is an Insignia6 dual magnetic die cutter running 20x17.5" sheets of presentation folders inline with a Chameleon folding/gluing system. These folders are diecut, scored, embossed, perforated and kisscut for glue assists, in a single pass. Also capable of running inline packaging work for folding cartons. For more information please visit www.insigniadiecutting.com or call (800) 272-4381 to speak with a Rollem sales representative.

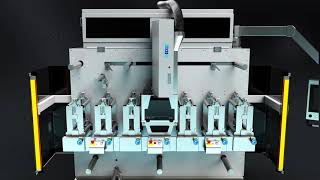

Precision Punch Assembly

Our modular punch assemblies have a punch-and-die design to make custom-shaped cut-outs. Available in pneumatic or electric configurations, our punch units use hardened-steel tooling that is clean-cutting and fast-acting. The assembly can be mounted in any orientation, so you can add it to any converting, processing, or assembly line in any way you see fit! Just bolt it on! #AZCO

Benefits:

Clean cutting

Fast acting

Easily moved

Mount in any orientation

Options:

Heated to seal synthetic fabrics

Custom shapes

Multiple punches and dies

Extra depth throat

Material guides

Sensors

UP-20 Precision Punch: http://www.azcocorp.com/up-20-preci...

Punch Assembly UP-40: http://www.azcocorp.com/up-40-punch...

Precision punch assemblies can be seen at the following link:

http://www.azcocorp.com/product-lis...

Single assembly components help make any custom job easier, check out these videos:

https://www.youtube.com/watch?v=AVf...

https://www.youtube.com/watch?v=zdl...

Follow us on your favorite social platform!

Facebook: https://www.facebook.com/AZCO-Corpo...

LinkedIn: http://www.linkedin.com/company/azc...

Google+ : https://plus.google.com/11006207813...

We are Delta ModTech

From our founding in 1978 as a service provider for servo systems and motion control in the machine tool industry, to today’s technology of full production Delta ModTech converting, coating and packaging lines, Delta ModTech has successfully pursued excellence in the design, implementation, and service of motion-controlled manufacturing systems. From tight tolerance die cutting to unique pouching requirements, Our machines are engineered for your toughest challenge.

https://www.deltamodtech.com

Increase your die cut capabilities with EDGE® Laser Technologyby Delta ModTech

We’ve been integrating lasers into our converting systems for over 15 years. We know the advantages of converting with laser die-cutting machines and we’ve seen our customers thrive on the increased capabilities it offers. Now it’s time for you to consider using laser die cutting and giving your company an edge over the competition.